We have already checked the specifications, done an unboxing, and shown how to assemble the LaserPecker LP5 2-in-1 fiber & diode laser engraver along with its safety enclosure and rotary extension in the first part of the review.

In the second part of the review, we will report our experience using the LaserPecker LP5 laser engraver with various materials such as plywood, stainless steel, rubber, and aluminum, as well as a ceramic cup and an insulated tumbler using either the LDS software on Windows or the LDS mobile apps on an iPad.

Using the LaserPecker LP5 laser engraver with LDS software

LaserPecker Design Space (LDS) is a laser engraving and cutting software designed specifically for the LaserPecker laser engravers. It’s meant to allow users to easily create projects with personalized engraving, complex patterns, and precise cutting of various materials. It can run on Windows and macOS with Intel or Apple (Arm) processors. Let’s download the software and install it on Windows.

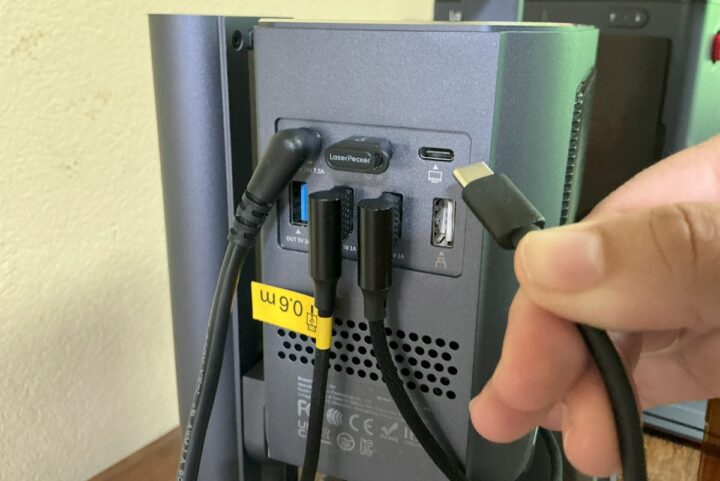

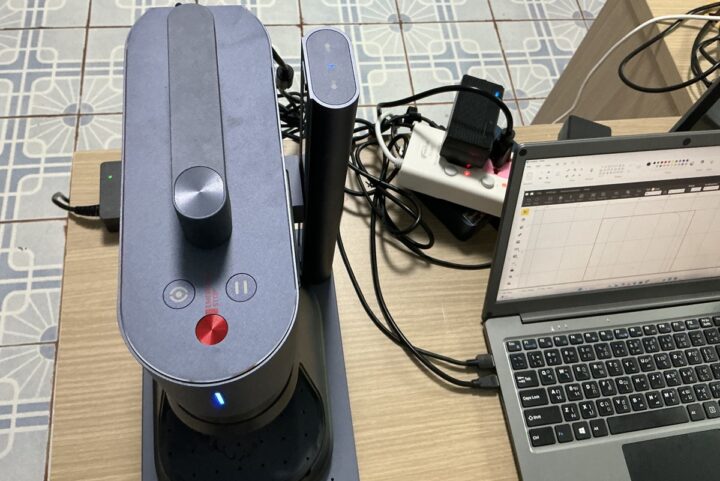

Now let’s connect the LP5’s USB-C computer port to our Windows mini PC using a USB-A to USB-C cable as shown below.

Note that when we connect the power adapter, the LaserPecker LP5 machine starts automatically with a (noisy) fan active. There’s no on/off button, only a (red) stop button.

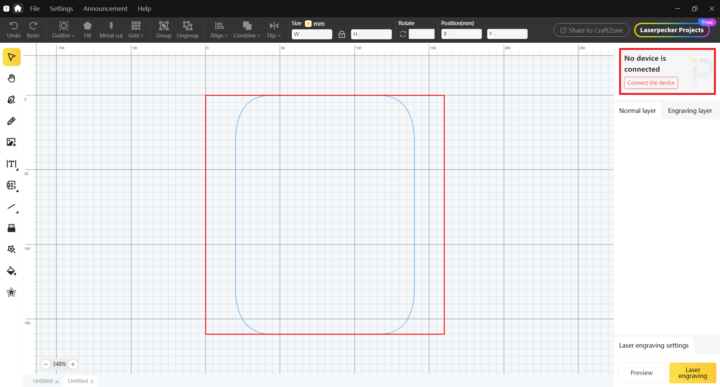

We’ll now launch the LDS software, and after registering an account online, we can click on Home->New project. The user interface will show “No device is connected” in the top right corner.

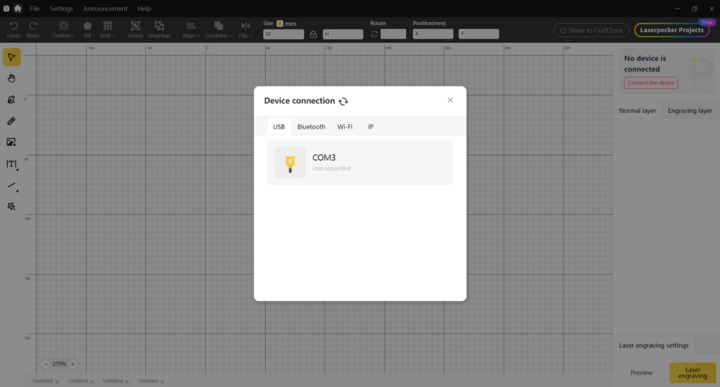

Clicking on the “Connect the device” button will bring up a “Device connection” window with a USB serial port, in our case: COM3. Bluetooth and WiFi connections are also possible.

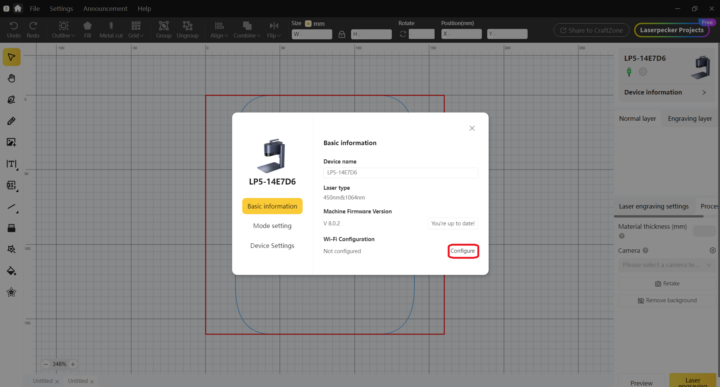

We can also configure WiFi after connecting via USB by clicking on “Configure”.

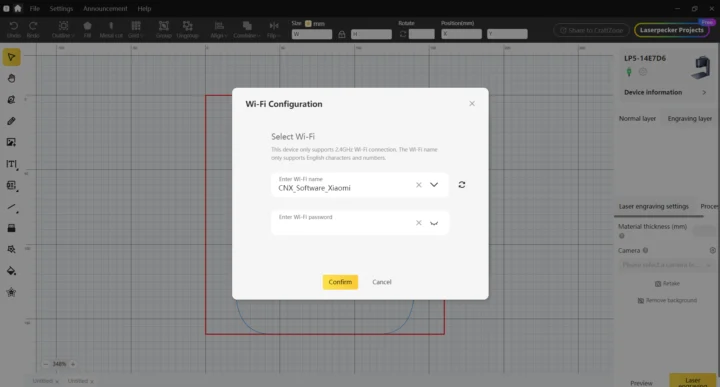

We can simply select the WiFi ESSID and enter the password, and we’re done. Note that the machine only supports 2.4 GHz WiFi networks, and if you select a 5 GHz WiFi network, it won’t connect.

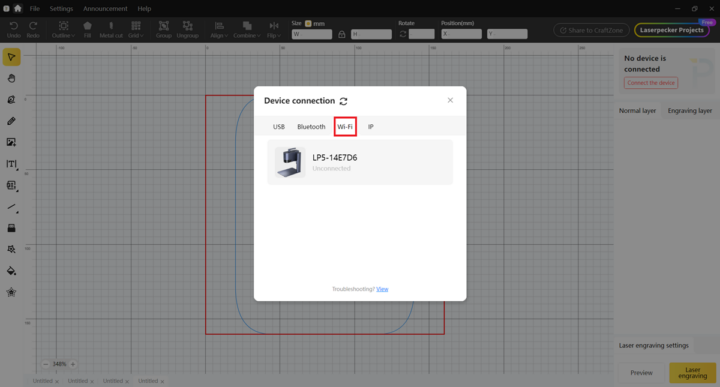

If we go to the Wi-Fi section in the “Device connection” Window, we’ll find our LP5 laser engraver. Click on it to connect.

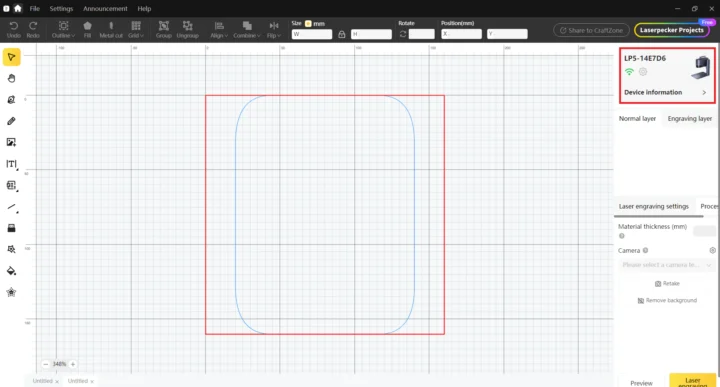

The LP5 will appear in the top right corner with a green WiFi icon.

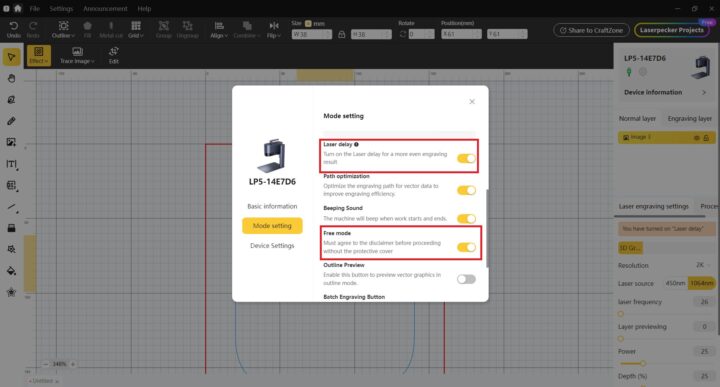

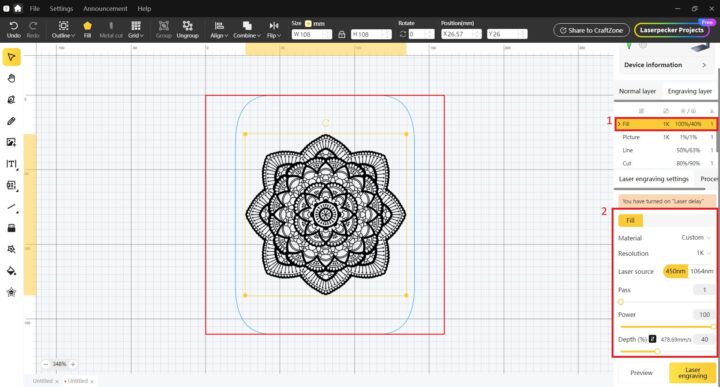

If you want to take pictures during the engraving or cutting process, you can enable Free mode to operate the machine without the protective cover. However, it’s not recommended as the laser may damage your eyes. We also activated the laser delay to have better results, especially when engraving text. Note that it might increase the time it takes to complete the piece.

In any case, you should also wear the light-filtering glasses while operating the machine.

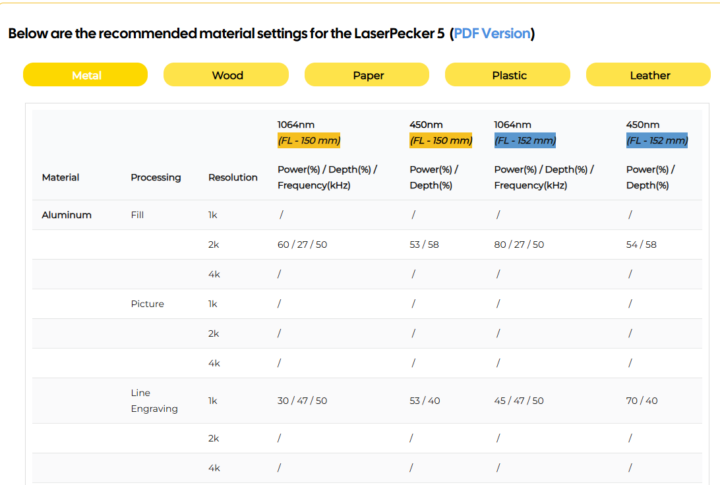

Different materials require different power, depth, and frequency, so LaserPecker provides a material settings table for the LP5. The screenshot below is just a subset of the parameters for metals; visit the aforelinked page for the full details.

The document provides recommended/reference power, depth, and frequency values for various materials such as aluminum, stainless steel, copper, titanium, wood, paper, plastic, leather, and more to help the user get started. For example, aluminum engraving at 2K resolution can use the following parameters:

- Fill, 1064nm (fiber) laser: Power 60%, Depth 27%, Frequency 50kHz

- Fill, 450nm (diode) laser: Power 53%, Depth 58%.

Note that those values are a starting point, and the user still needs to experiment to get the best value for the materials and desired results.

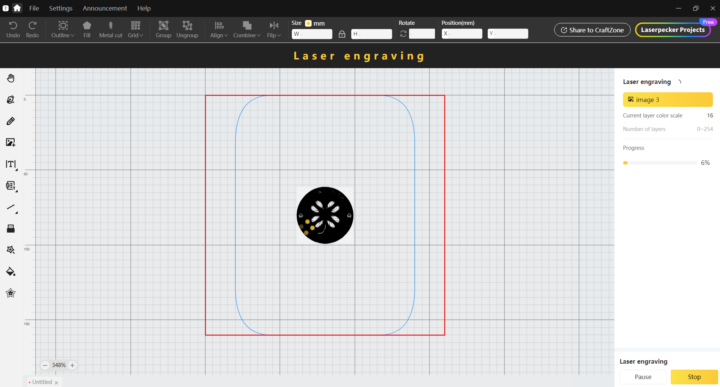

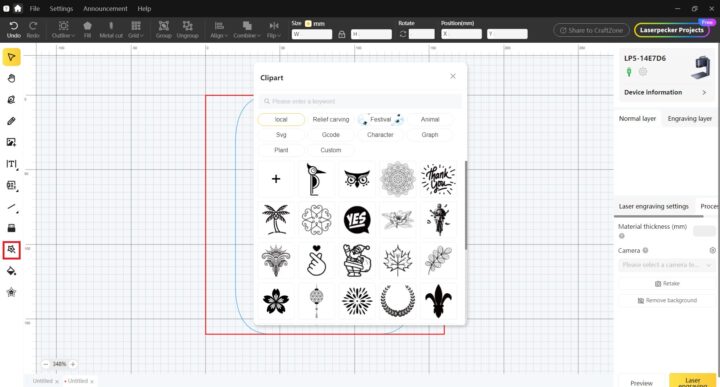

Let’s try our first engraving. We can select some pre-defined designs from the Clipart tool.

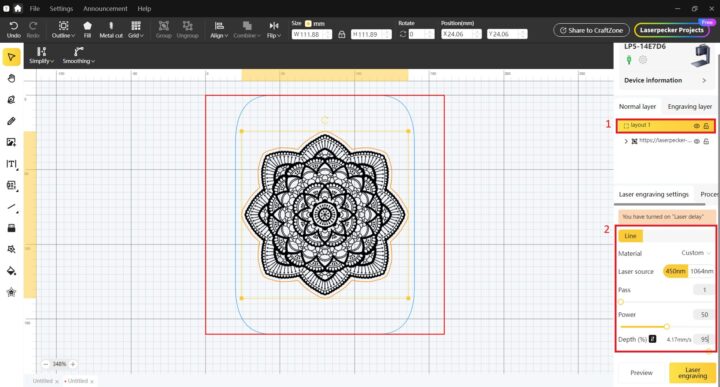

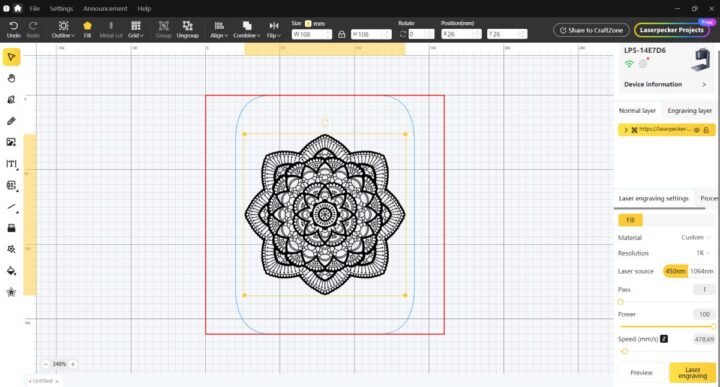

We opened the Mandala sample.

From there, we need to select the processing type (Fill, Picture, Line, Cut), laser source of the engraver (450nm diode laser or 1064nm fiber laser), the number of passes (1), the power in percent (100%), and depth (28%) in percent.

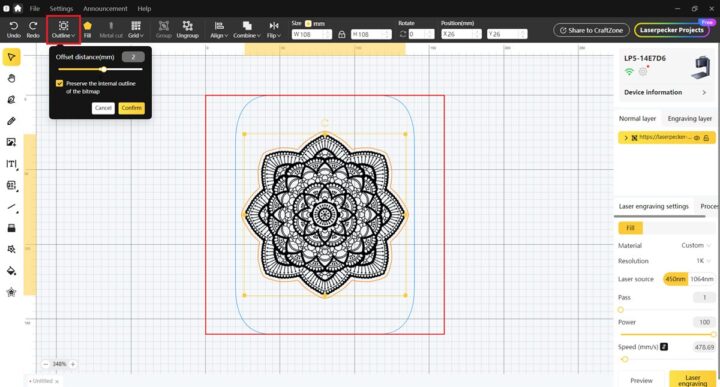

Since we are also going to cut the workpiece after engraving, we added a 2mm offset distance using the Outline menu. You can see a brown line that follows the shape of the Mandala.

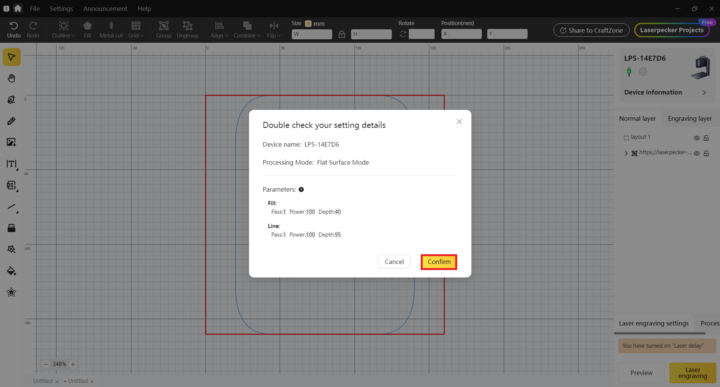

We can then double-check that a new layer “layout 1” has been added to the right sidebar, and adjust the depth of the edge layer to 95% and set the power to 50% so that the LaserPecker LP5 cuts out that part. Instead of using “Fill” for the clipart, we used “Line” to cut it.

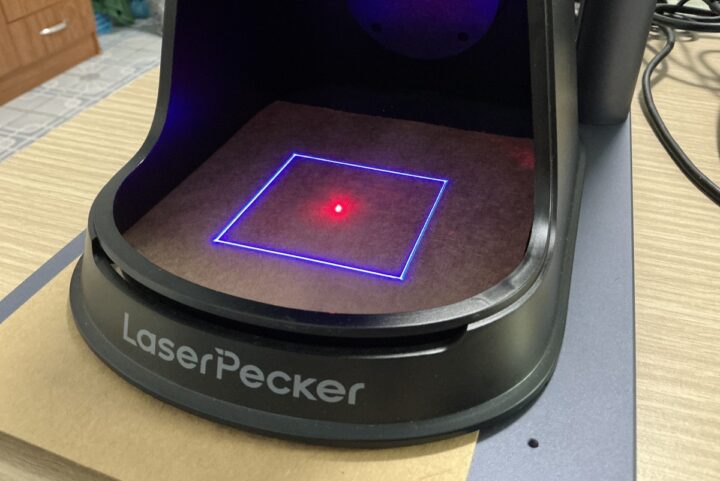

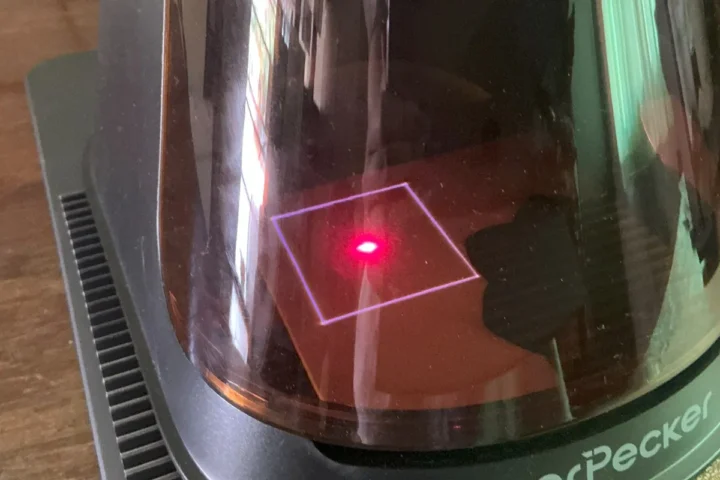

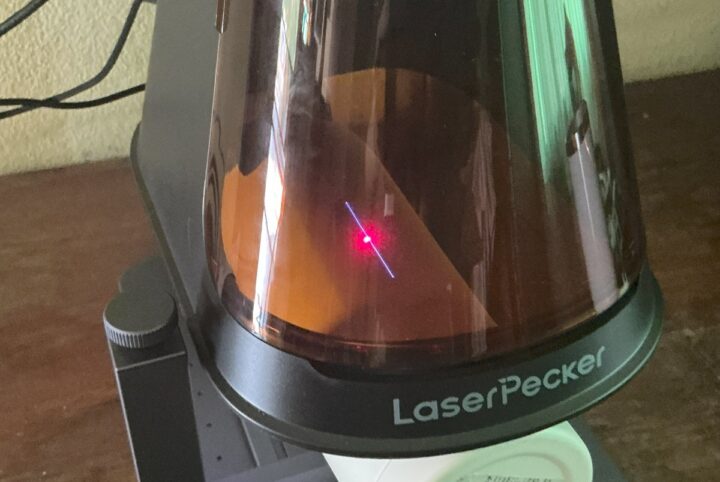

It’s important to focus the laser and check the engraving area (framing) on the material before proceeding with the engraving and cutting. The LaserPecker LP5 relies on two red dots for focusing. You can focus the laser by merging the two red dots into one, either by using the up and down arrows on top of the electric stand or the up and down arrows on the preview button in the program. A blue rectangle conveniently shows the area of the materials that will be worked on.

The blue frame light will only appear when we click on the Preview button in the program. We could not see the blue light initially, so we contacted the company about this issue. They quickly replied, suggesting we increase the brightness. We did that (set to 100%), and that fixed it. The suitable brightness will depend on the material and work environment.

We can now click on the “Preview button” for a dry run to check where the laser will point. There’s no need to wear protective glasses during the preview, since the laser is not active, and you may have trouble clearly seeing the blue light. You may also consider removing the cone-shaped protective cover during preview, since the light is dim with the cover attached.

When you are sure you want to go ahead, press confirm to start engraving and cutting

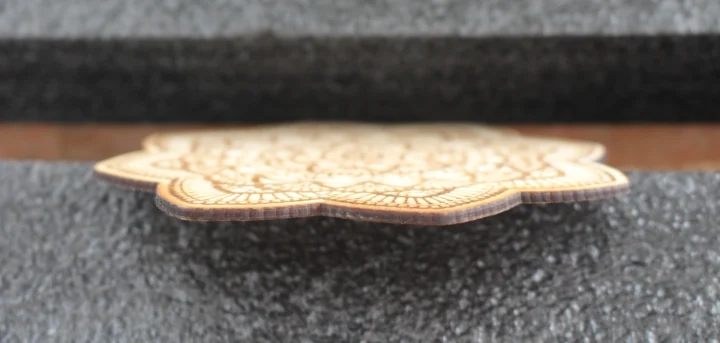

First engraving and cutting on plywood

Now that everything is configured and we are satisfied with the preview, let’s try to engrave the Mandala on the plywood plate (108x108mm) part of the kit with the following parameters:

- Resolution: 1K

- Processing mode: Fill

- 450nm diode laser: Power 100%, Depth 40%, pass 1, speed 478.69 mm/s

It took 2 minutes and 21 seconds to complete the engraving process. Let’s now cut the piece with the following parameters:

- Resolution: 1K

- Processing mode: Line

- 450nm diode laser: Power 100%, Depth 95%, 1 pass, speed 4.17 mm/s T

It took 1 minute and 24 seconds to cut the piece, or 3 minutes and 45 seconds for engraving and cutting.

Since we did not use a honeycomb plate, there are marks on the base plate, as well as small burns on the workpiece itself. Some machines come with an air assist pump, but there’s no such option for the LP5. The company advised us to lower the depth and use two passes to reduce the burns, but we were out of material and time to test that.

Aluminum alloy test

The next test was to engrave a black and white cartoon (51.5 x 43.3mm) on an aluminum alloy card with the following parameters:

- Resolution: 8k

- Processing mode: Picture

- 1064nm fiber laser: Power 5%, Depth 1%, Frequency 60kHz, 1 pass

This is our first test of the LP5 engraver with the fiber laser, and the result looks really nice. It took 12 minutes to complete.

Using the LaserPecker LP5 laser engraver with the safety enclosure

Our kit also comes with a safety enclosure that’s even safer to use than with the protective cover and glasses. After placing the LP5 on top of the enclosure, we connected two USB-A cables and the power adapter cable as shown in the photo below.

The emergency stop button was activated, so we had to turn it clockwise to release it and turn the machine on.

Aluminum alloy test with the safety enclosure.

We used another aluminum alloy card to engrave an elephant (51.5 x 43.3 mm) with the following parameters:

- Resolution: 8k

- Processing mode: Picture

- 1064nm fiber laser: Power 5%, Depth 1%, 1 pass

We then tried to cut the shape around the elephant with the following parameters:

- Resolution: 1k

- Processing mode: Line

- 1064nm fiber laser: Power 100%, Depth 90%, Frequency 60kHz, 16 passes, speed 10.64 mm/s

It did not work the first time, so we did that twice. Increasing the number of passes should have the same effect.

It took 19 minutes and 55 seconds in total.

Leather engraving and cutting

Next up was testing the LP5 with leather. We used a Mandala (46.8×48.03 mm) with the following parameters:

- Resolution: 1k

- Processing mode: Fill

- 450nm diode laser: Power 100%, Depth 40%, 1 pass, speed 478.69 mm/s

After that, we cut around the shape of the Mandala (49.78 x 51.01mm)

- Resolution 1k

- Processing mode: Line

- 450nm diode laser: Power 50%, Depth 95%, 1 pass, speed 4.17 mm/s

Total time: 9 minutes and 51 seconds

Stone slate coaster engraving

We engraved a flower (72.67 x 80.74mm) on a black stone slate coaster with the following parameters:

- Resolution: 2k

- Processing mode: Fill

- 1064nm fiber laser: Power 100%, Depth 25%, 1 pass

It took 6 minutes and 32 seconds in total.

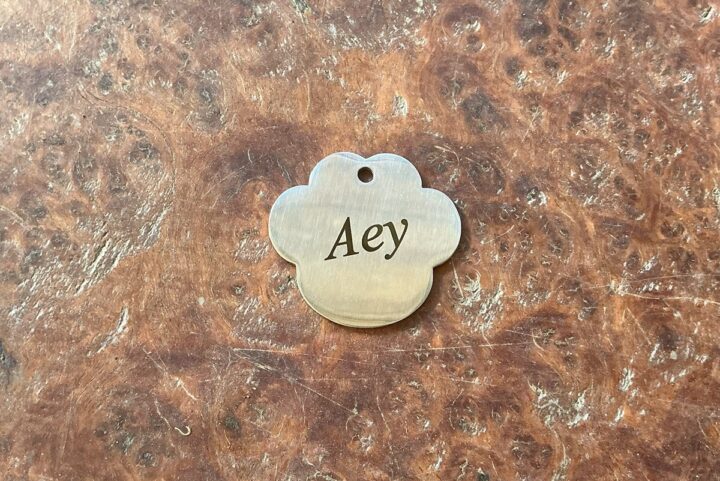

Stainless steel necklace pendant test

Parameters:

- Resolution: 1K

- Processing mode: Image

- 1064nm fiber laser: Power: 100%, Depth: 60%, Passes: 1

That one only took 41 seconds to complete.

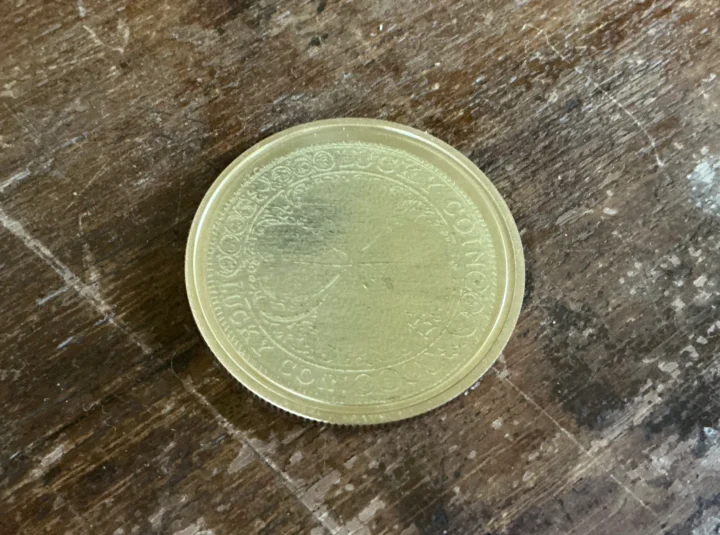

Brass coin test

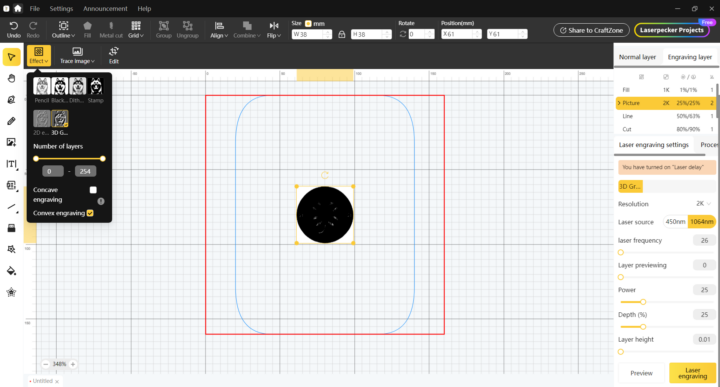

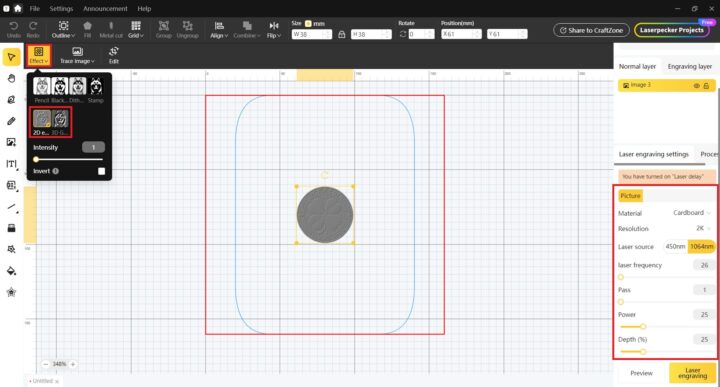

We import a coin design and set it to either 2D or 3D mode.

3D mode will look much better, but it also takes several hours (5 to 8 hours)

We started in 2D mode (38 x 38 mm design) with the following parameters:

- Resolution: 2K

- Processing mode: Picture

- 1064nm fiber laser: Power 25%, Depth 25%, Frequency 26 kHz, 1 pass

It took 6 minutes and 15 seconds to complete.

The result is underwhelming… So we switched to 3D mode with the same parameters, but there are now 254 passes instead of just one, so it’s going to take a lot of time (a few hours).

Sadly, the process stopped at 40% after a few hours. We contacted the company, and they told us to disable sleep mode on the computer and use USB instead of WiFi. That was already our configuration, but we tried again, and it “completed” in about 13 hours, but the laser did not fire… It happens from time to time, so make sure the laser is active when starting a job. We stopped here due to a lack of time. Maybe we’ll try again later. Here’s what the coin looks like after 40% of the engraving process.

That’s what the full coin is supposed to look like:

Comparison – Engraving with and without the LP5 safety enclosure

While there’s ventilation in the LP5 safety enclosure, we wanted to see if there were any differences for engraving a piece with the same settings, either without or with the safety enclosure.

We did that by engraving Linux Tux (26.17×39.25 mm) on a wooden keychain with the following parameters:

- Resolution: 1K

- Processing mode: Fill

- 450nm diode laser: Power: 100%, Depth: 40%, Passes: 1

It only took 26 seconds.

Here are the results.

The sample done inside the safety enclosure does not look good, with the right side of the Tux having severe burns. We initially thought it may be because of less ventilation inside the enclosure, but after trying to engrave “CNX Software” on the back side, both methods yield similarly good results.

So it’s not 100% clear whether the burns for the engraving in the first photo are simply due to inherent differences in the material, some ventilation issue, or something else. Experimenting with your model/material combination is key. Lowering the depth and/or power, and increasing the number of passes, may help prevent burns, but it increases the time it takes to complete the piece.

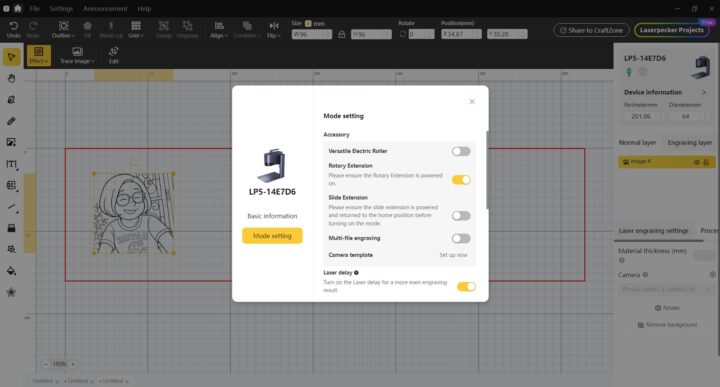

Review of the LaserPecker LP5 with the rotary extension

If the connection is established successfully, the blue LED will turn on above the USB-C port on the rotary extension.

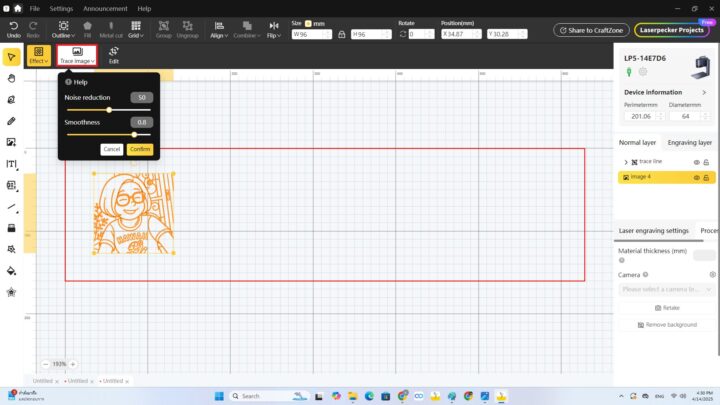

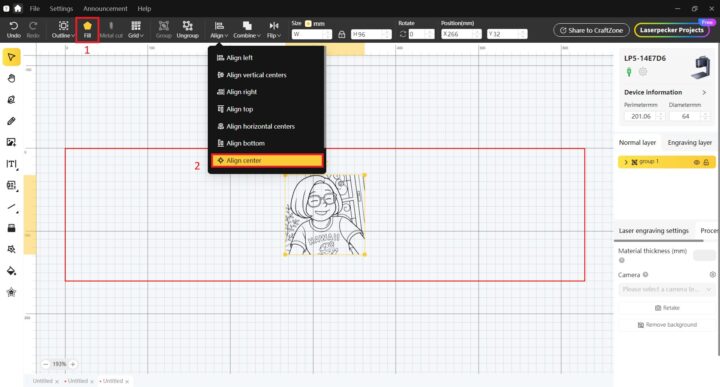

We can then import an image into the program and remove the background (if any) using the Magic Eraser tool.

After that, click on Trace Image, then Confirm. Once done, delete the image layer (image4).

Click on the Fill icon to enable color filling for the layer and center it (align center). Set the size according to your needs, and don’t forget to adjust the perimeter (mm) and diameter (mm) parameters to match the dimensions of your mug, glass, cup, or bottle.

This is what it looks like when running the preview. The blue light will only scan the area of the design. If it scans the full perimeter of the mug, you probably forgot to set the perimeter/diameter values or set them wrong.

Engraving on an insulated tumbler

Our first test with the rotary extension was with an insulated (stainless steel?) tumbler with the following parameters:

- Resolution: 4K

- Processor mode: Fill

- 1064nm Fiber laser: Power: 100%; depth: 50%; Passes: 1

It took 14 minutes and 32 seconds to complete.

The results look fairly good, although there are some burns. You can ignore the small dots and marks on the tumbler as they are simply the result of a previous attempt with the wrong perimeter/diameter…

Porcelain cup test

The next test was done on a porcelain cup with the following parameters:

- Resolution: 4K

- Processing mode: Fill

- 1064nm fiber laser: Power 100%, Depth 10%, Pass 1

It took 11 minutes and 57 seconds to complete.

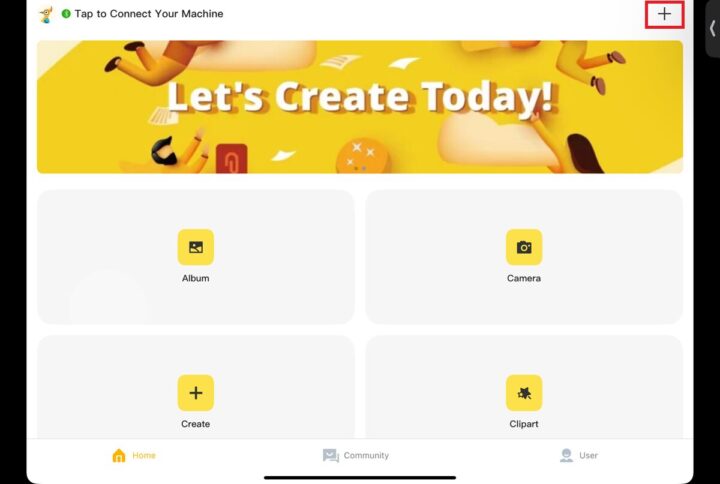

Using the LaserPecker LP5 with the LDS mobile app

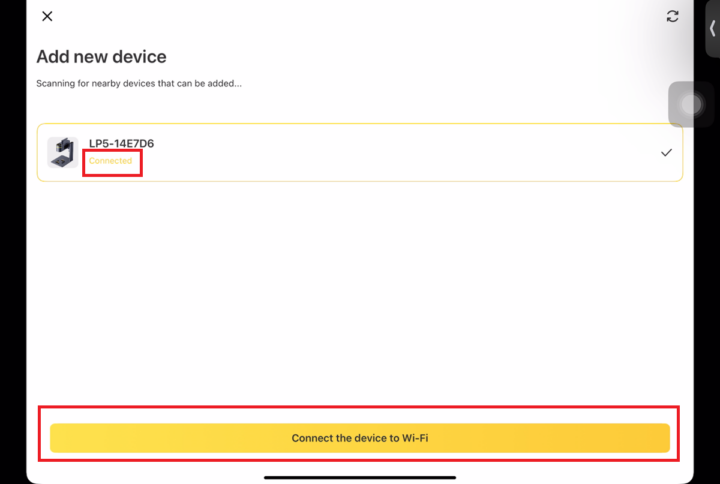

If you don’t own a computer or simply prefer to use a mobile device or a tablet, the LP5 engraver can also be used with the LaserPecker Design Space (LDS) mobile app available for iOS and Android. We installed it on an iPad. Once the app is up and running, press the + button in the upper right corner and select LP5-XXXXXX.

Then tap on “Connect the device to Wi-Fi”.

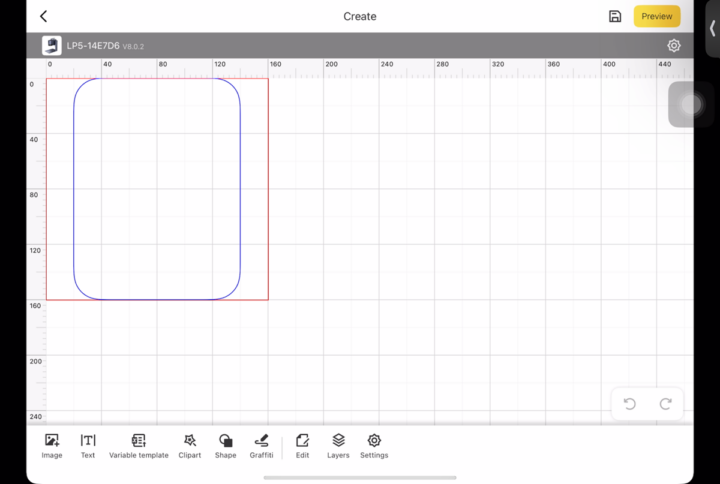

We can now tap on the Create button to start a new project.

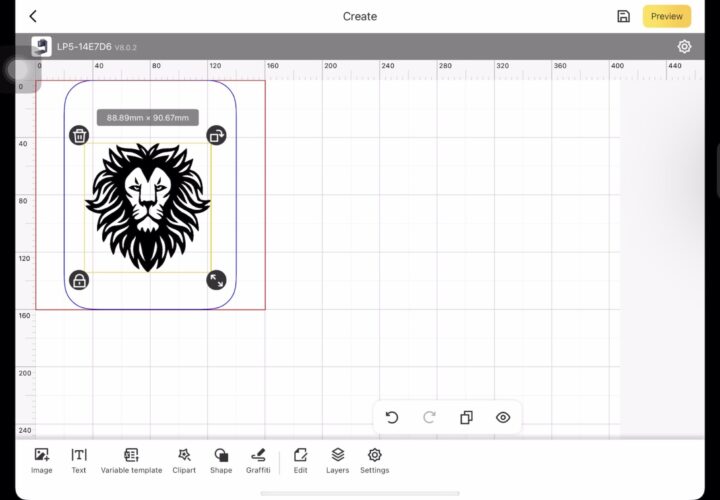

Let’s select a clipart: a lion head.

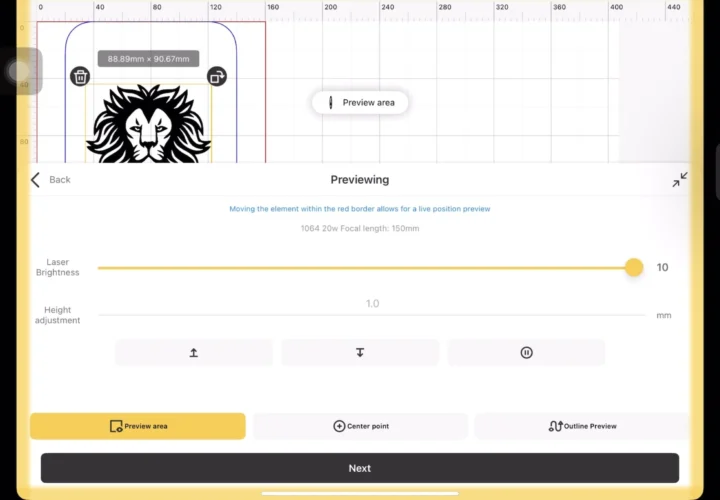

Go to Preview to check the engraving area.

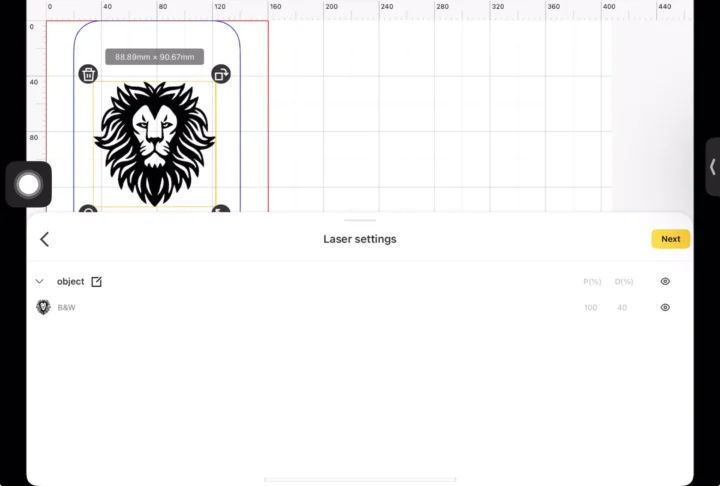

We can now configure the laser engraver as follows:

- Resolution: 1K

- Processing mode: Fill

- 450 nm diode laser: Power 100%, Depth 40%, 1 pass

Tap on start, and the engraving process will take about 3 minutes and 24 seconds.

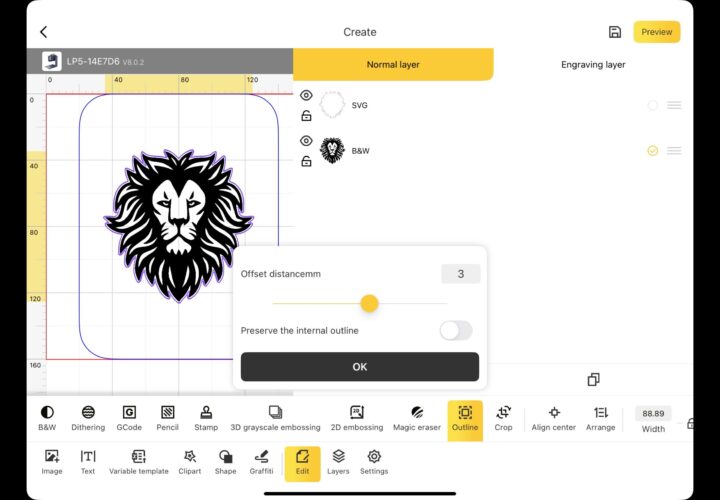

We’ll also want to cut the shape of the lion’s head. We want the border to have a 3-millimeter margin from the design.

Cutting parameters:

- Resolution: 1K

- Processing mode: Line

450 nm diode laser: Power 70%, Depth 90%, 3 passes

The cutting part took 1 minute and 15 seconds.

Here’s the result. The app is fairly easy to use and similar to the LDS program. Once you know how to use the machine and the LDS program, switching to the app is rather straightforward.

Conclusion

The LaserPecker LP5 is a portable laser engraver with a 2-in-1 diode and fiber laser module that supports a wide range of materials such as leather, stainless steel, wood, and aluminum. The company provides software for Windows and Mac computers, as well as Android and iOS devices. Documentation may need to be improved as the reviewer (Kuljira) initially struggled to use the machine. But once the LP5 and LDS software operation was better understood, we could produce sharp and details workpieces that look quite better than on cheaper diode laser-only machines such as the TwoTrees TS2 we reviewed in 2023.

There were some downsides, too. We had some pieces with burns despite using recommended parameters, partially because the LP5 does not support air assist but relies on its built-in fan only. We also struggle working on brass coins as it takes a lot of time, several hours. We were also surprised by the lack of a power button to turn the machine on or off, so as soon as the power is applied, the machine runs with its noisy fan. Some people may lament the lack of a touch screen display for control, and you need to use a computer, phone, or tablet, and the work area of 120 x 160 mm (eclipse) or 100 x 100 mm (square) is smaller than for less portable laser engravers.

The safety enclosure effectively reduces noise and shields harmful light from affecting the eyes, although the cone-shaped protective cover already does a good job for the latter. A benefit of the safety enclosure is its emergency button that can also serve as an on/off button lacking on the main unit. The rotary extension is a great addition for work on cups, mugs, tumblers, bottles, etc…

iPad users may prefer using the LaserPecker Design Space (LDS) app rather than the LDS program on Windows or Mac, but note that there are limitations, such as the inability to use the Fill or black color fill feature on the app.

We’d like to thank LaserPecker for sending the LP5 laser engraver, rotary extension, and safety enclosure for review. The LP5 2-in-1 fiber/diode laser engraver sells for $2,899 with a free material pack, the rotary extension goes for $319, and the LaserPecker LP5 safety enclosure for $599. Alternatively, you’ll also find the LaserPecker LP5 on Amazon for the same price after ticking the $400 off coupon, and the rotary extension is offered as an option. The safety enclosure is also available on Amazon, but on a separate page. We initially thought the price was quite high, but after looking for alternative engravers with 20W fiber and diode lasers, we only found the xTool F1 Ultra that retails for close to $4,000. However, it does offer a larger working area and built-in features such as a camera and touchscreen controller.

CNXSoft: This review is a translation, with some edits and additional insights, of the original review on CNX Software Thailand by Kuljira Suthinee, with assistance from Suthinee

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress