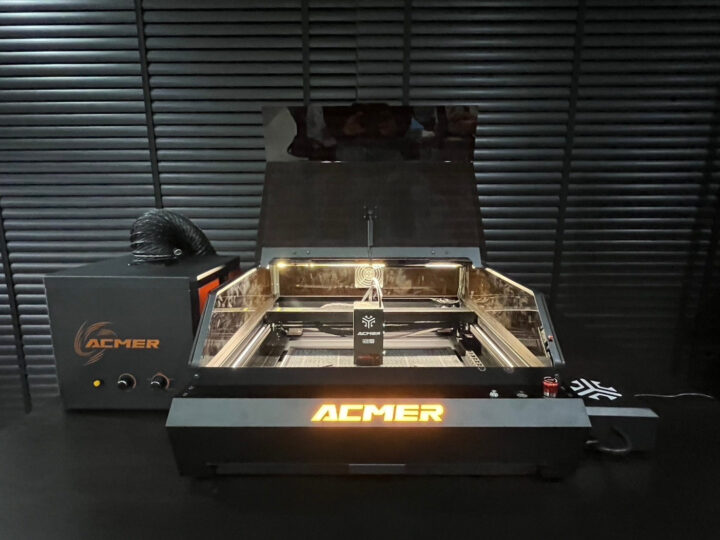

Today, we’ll review the ACMER P3 48W laser engraver suitable for engraving and cutting various materials such as wood, acrylic, leather, and coated thin metals. It has a fully enclosed design protecting against laser light and reducing smoke in the room for better safety.

The laser engraver also supports air filtration through the ACMER AP220 air purifier which we received for review as part of a full kit. Additionally, the P3 48W comes with a built-in camera for precise work positioning and previewing before engraving or cutting begins. Other safety features include automatic operation shutdown when the machine cover is opened. Users can import files through USB, Wi-Fi, or SD card, and the machine is compatible with popular software like LightBurn and LaserGRBL, as well as the ACMER mobile app, making it easier to use with file formats such as PNG, JPG, SVG, and DXF.

ACMER P3 48W laser engraver highlights

- CoreXY structure with 800mm/s Max Engraving Speed allowing high-speed and accurate engraving

- Two laser power options

- 48W for cutting thick or hard materials, such as thick wood or painted meta; can cut through up to 45mm dark acrylic

- 24W for engraving work that emphasizes details and sharp patterns, such as creating art

- HD camera to help users position materials and monitor engraving patterns – 400x400mm visualization area

- Compatible with ACMER APP, Lightburn, and LaserGRBL; support for PNG, SVG, JPG, and DXF file formats

- Support for 2-in-1 and 2W laser modules for switching between infrared (IR) lasers and general lasers to increase the variety of cutting and engraving materials

- Expandable working size up to 4000 mm (4 meters) for large jobs

- FDA Class 1 safety for user safety with a structure and features that protect users from laser and toxic smoke

The ACMER P3 48W laser engraver is designed with an 8-layer safety system as described below.

ACMER P3 48W laser engraver preparation and assembly

Let’s get started with the review by preparing and assembling the ACMER P3 48W laser engraver. The laser engraver ships with a belt lock to prevent damage during transportation, and to first step is to remove it so that the belt can move normally.

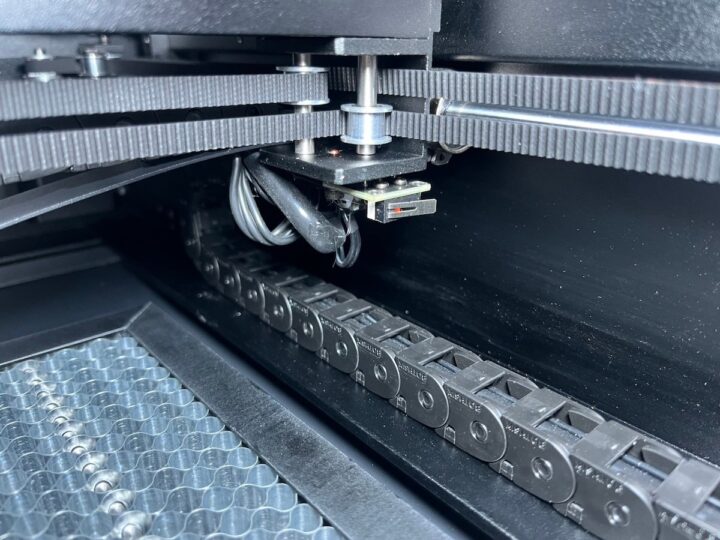

The linear guide inside the ACMER P3 laser engraving machine is designed to work with the CoreXY system which is a structure that can control the movement in the X and Y axes efficiently. It allows the laser head to move accurately in the specified direction. The motor will transmit power through the timing belt to move along the slide rail. This system is designed to support both high-speed work and work that requires a high level of detail.

The X and Y limit switches will stop the laser head when it reaches the limits of the X or Y axis to prevent damage. It also helps to define the working area of 400 x 400 mm and is used for homing before starting engraving or cutting to increase the accuracy of the work.

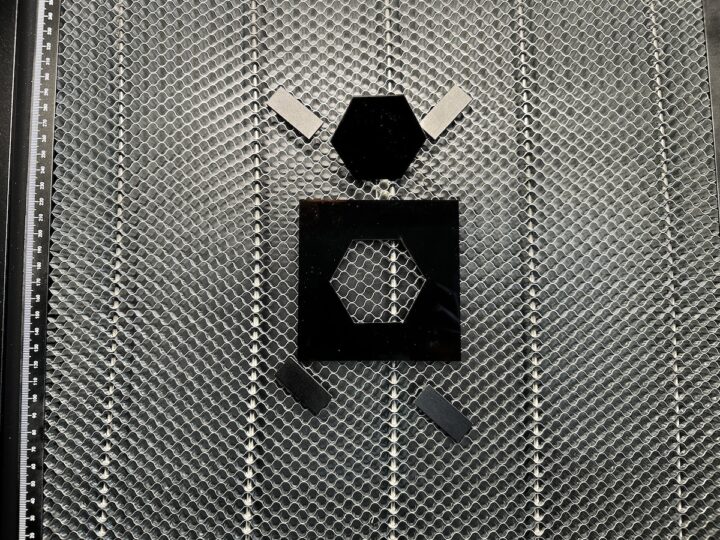

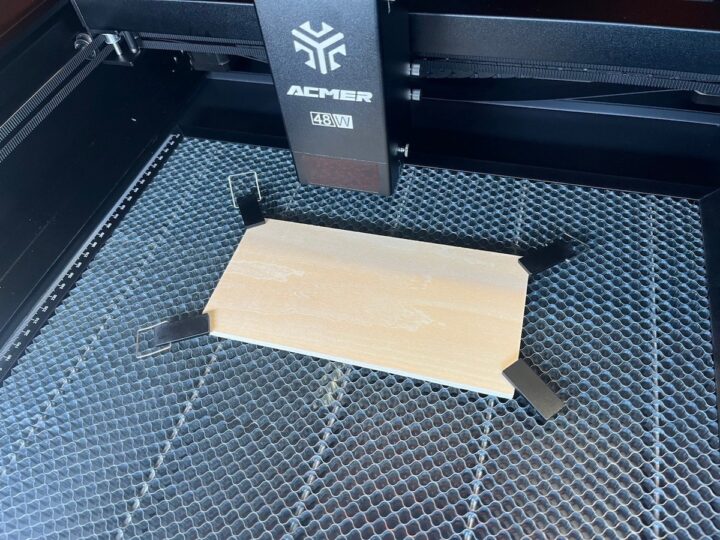

The kit ships with a honeycomb base plate that allows air and smoke to flow freely. It can distribute the force from the laser firing evenly on the material, reducing damage to the surface and preventing laser burn marks.

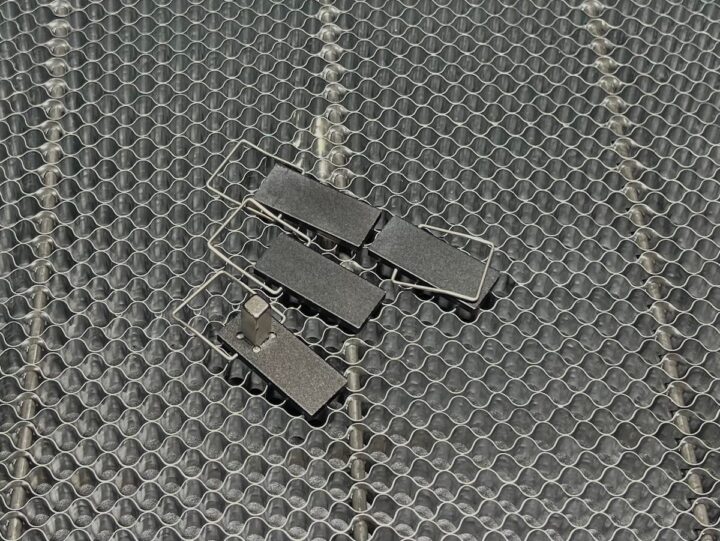

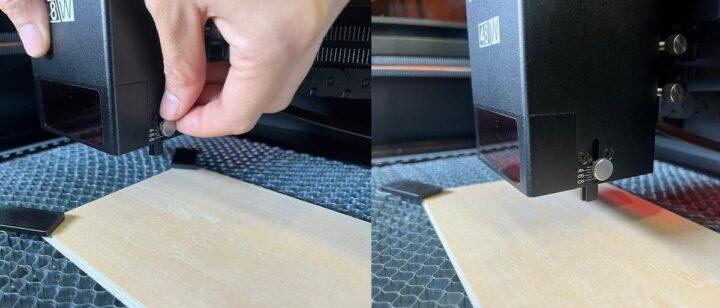

It’s also convenient to keep the workpiece in place, and for that purpose, four magnetic material clips are part of the kit.

They can be inserted into the honeycomb plate to keep the workpiece in place even with vibration during operation for better results.

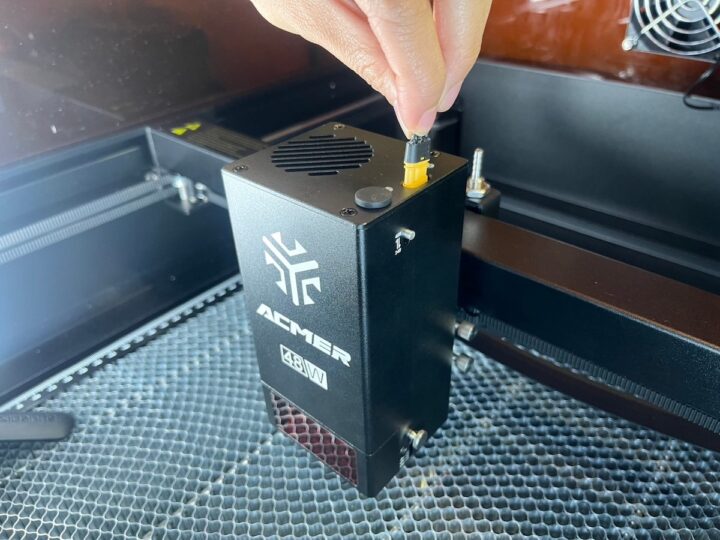

ACMER P3’s laser module has a switch to select the laser power between 24W and 48W. The laser light wavelength is 445 to 450nm (blue laser light), and there’s a filter lens to help reduce the reflection of the laser light.

We now need to mount the laser module on the ACMER P3 48W’s sliding rail system.

We can then connect the power cable with an XT30 connector…

… before inserting the air pipe from the Air Assist system into the opening next to the power cable. The other end of the air pipe is connected to the air pump system at the back. This will help reduce the heat around the laser head, blow air to remove debris, and reduce the accumulation of smoke, resulting in higher-quality engraving or cutting work.

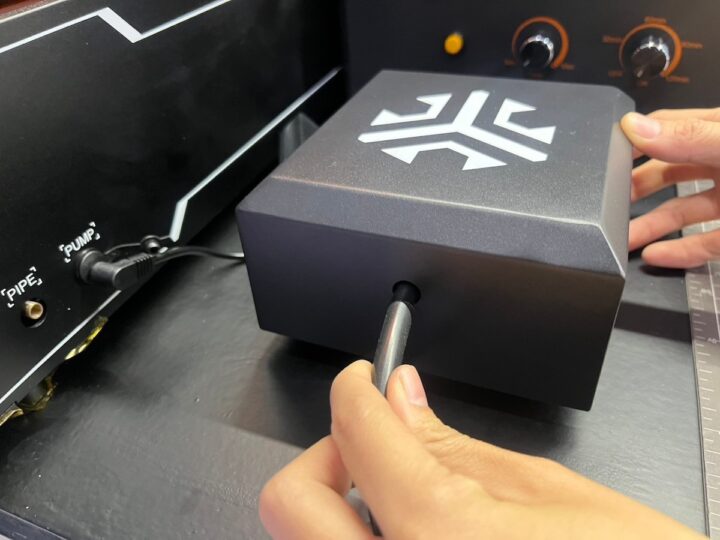

The next step is to adjust the focus distance of the laser. We’ll move the laser head above the workpiece and then turn the height adjustment screw of the fixed-thickness platform to adjust the focus distance between 4 to 8 mm. Once the focus level touches the workpiece, we can adjust the height back to its original position.

The laser engraver ships with safety glasses which should be worn at all times when the machine is operating. Also, avoid looking directly at the laser beam even with the glasses on to prevent eye injury.

The air pump that ships with the ACMER P3 48W laser engraving machine helps increase the efficiency of engraving and cutting materials by blowing air at approximately 30 liters/minute for high-speed work.

First, connect the power supply to the PUMP port of the ACMER P3 48W laser engraver…

… and then connect the pipe between the air pump and the machine.

The ACMER P3 ships with a 100-240V AC to 24V DC/9A power adapter with overvoltage and overcurrent protection to prevent damage to the machine.

The DC input can be found on the left side of the laser engraving machine.

The ACMER P3 48W laser engraver also comes with a Key Switch system (safety lock) to prevent unauthorized use and accidental power-on making it suitable in places with children or untrained users. Once unlocked, the machine can be powered on by pressing a switch and potentially stopped with a red emergency stop button in case of emergency such as a fire or a malfunction.

The ACMER P3 48W also has two extra switches on another side: one light switch and one fan switch whose functions are self-explanatory.

The Low Flow Switch (ON/OFF) is used to control the airflow. The ON mode turns on the Low Flow system to help reduce smoke and prevent the material from burning and should be used for heat-sensitive materials such as wood or acrylic, and when cutting. The OFF mode can be for low-power engraving.

As noted in the highlights section, the laser engraver has a built-in 1080p camera installed on its cover to help users position the workpiece and preview the pattern before starting the engraving or cutting process. The camera improves the accuracy of material and pattern positioning, and the accuracy of engraving pattern placement can be checked directly on the software.

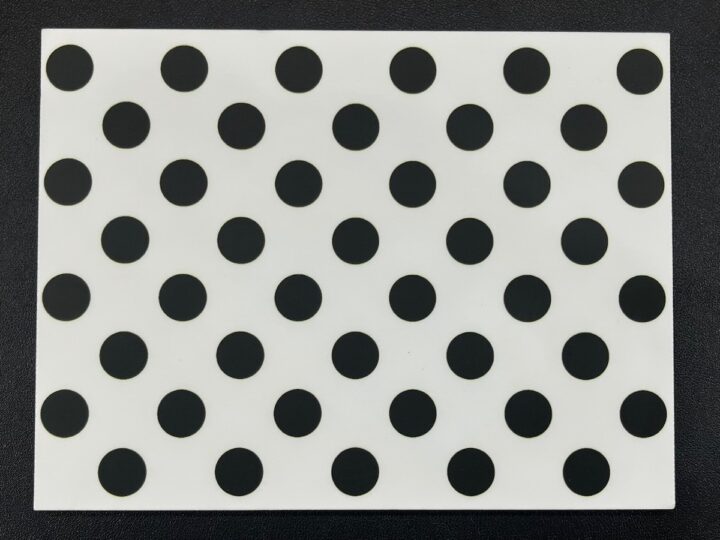

ACMER also provides a calibration plate for the camera. The black dots on the white background are arranged in a specific pattern so that the software can analyze and adjust the position of the camera accurately.

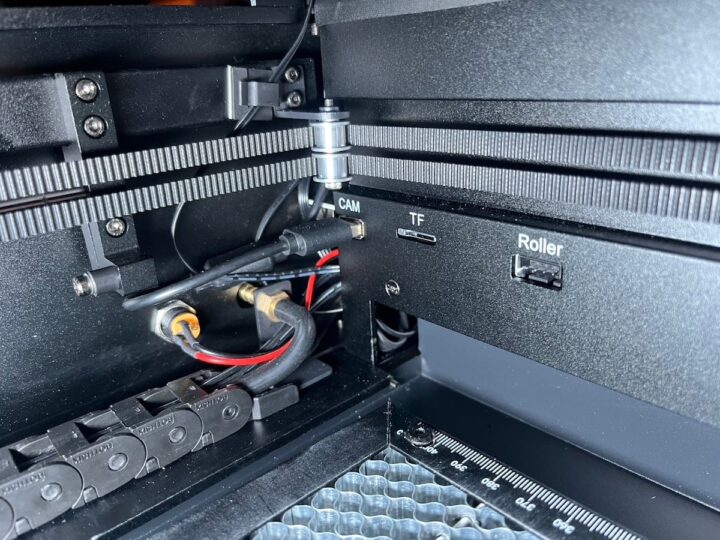

The camera is connected to the machine through a USB port close to the microSD “TF” card and Roller accessory slot (not used in this review).

The machine also comes with a few tools kept in a plastic box:

- Wrench and screwdriver for adjustment and assembly

- Cleaning brush for cleaning debris or dust in the work area

- Straps and other accessories for cable management

- Grease used to lubricate moving parts such as slide rails to ensure smooth operation and reduce wear

- Accessory connection cable for connecting various accessories

- Keys used to control the power on-off

- Lens cleaning cloth for cleaning the laser lens

There’s also some documentation and materials like basswood and cardboard which we’ll use later

ACMER AP220 Smoke Air Purifier

The AP2200 smoke air purifier is a device used to reduce smoke, dust, and unpleasant smells, and absorb chemicals from smoke or materials cut by lasers. It has an exhaust fan that helps draw smoke into the filter quickly. It helps purify the air in the work area reducing the accumulation of dust and smoke in closed areas.

Key features of the ACMER AP220 smoke air purifier include a high-speed 4000 RPM exhaust fan, an air volume of 210 m3/h to remove smoke and harmful substances, three layers (primary cotton/HEPA/high-efficiency composite activated carbon) to absorb all smoke, dust (PM2.5) and harmful gases with a 99.97% filtration and purification effect, and a 75-100mm pipe diameter is suitable for most closed laser engraving machines. It also offers a timing function and an adjustable fan speed. The AP220 is relatively quiet with a maximum noise of 55dB.

The exhaust pipe and pipe lock need to be mounted to the air purifier as shown in the photo below. The exhaust pipe helps draw out the fumes and dust generated during engraving from the work area, while the pipe lock is made of strong metal and is used to hold the pipe tightly.

- Squeeze the tube lock to widen the ring

- Slide the end of the exhaust pipe into the exhaust port of the engraving machine

- Release the lock to allow the ring to squeeze the pipe tightly preventing it from being detached during use.

This method allows the exhaust pipe to be firmly and securely attached to the port and is also convenient for removal and reinstallation if it needs to be moved or changed.

The air purifier should be installed near the laser engraving machine in a way that it is close to the exhaust of the P3 48W. The air purifier should be turned on during operation for air filtration to work. The condition of the filter should be checked periodically and either cleaned or replaced when suitable to maintain efficiency and extend the life of the filter system.

The ACMER AP220 comes with air pressure and timer adjustment buttons. The left button is used to adjust the air pressure of the air filter system from Min for low air pressure for jobs with little smoke, and to Max for high air pressure. The right button is used to set the operating time. You can choose between 30 minutes, 60 minutes, 90 minutes, or 120 minutes, turn to NO for constant operation, or turn to OFF to turn it off.

Sadly our sample did not seem to work at all. The AP220 Air Purifier would turn on, but the motor wouldn’t spin. So we can’t comment too much on that part. The company is currently on holiday for Chinese New Year and doesn’t reply to support requests. We’ll update the review once/if this is solved.

ACMER P3 48W laser engraver PC connection, engraving/cutting parameter, and software options

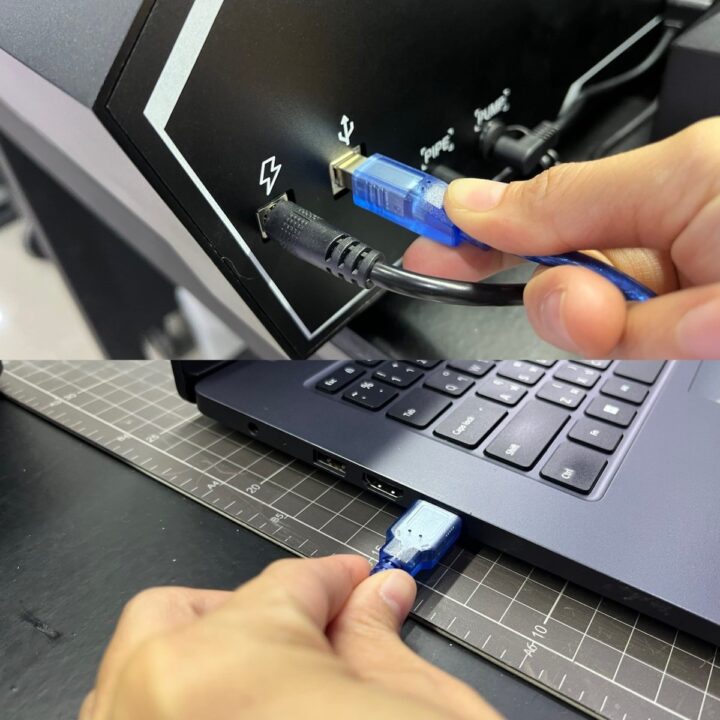

We can now connect the ACMER P3 48W laser engraver to a host computer through a USB Type-A to USB Type-B cable. This will allow the computer to control the machine using programs such as LightBurn or LaserGRBL by sending files and commands.

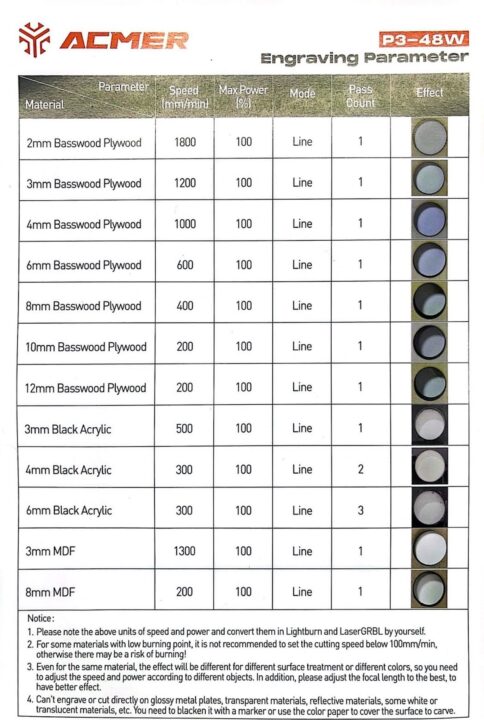

In this part of the review, we will refer to two tables to select speed and laser power. The cutting parameter table shows the optimal setting values for a variety of materials, such as basswood/plywood (2mm – 12mm), black acrylic (3mm – 4mm), and MDF (Medium-Density Fiberboard) (3mm – 8mm) with columns for the Speed in mm/min, the Max Laser Power in 100%, Mode (Line), and Pass Count, and an Effect column showing some examples.

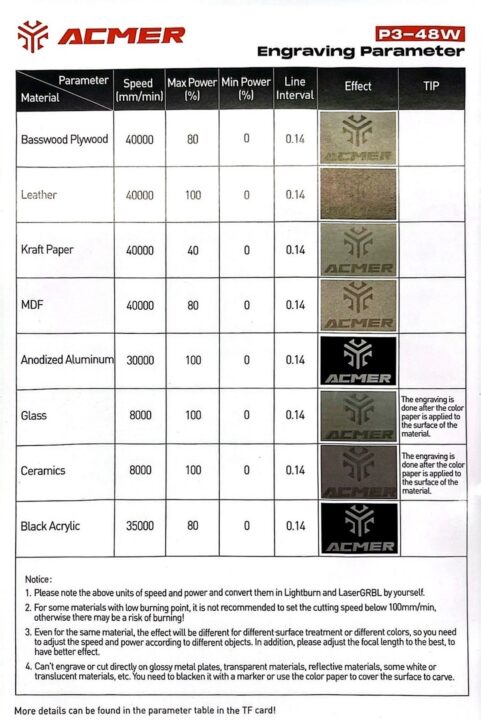

The second table is for engraving and defined optimal parameters for basswood/plywood, leather, kraft paper, MDF, anodized aluminum, glass, ceramics, and black acrylic. The table has four columns for the Speed, Max/Min Power, and Line Interval values. It also has two additional columns with photos of examples and tips.

The ACMER P3 48W laser engraving machine ships with a few materials to let users experiment with engraving and cutting settings. The package includes balsa wood and plywood for testing resolution, acrylic sheets for viewing results on translucent or opaque materials, cork sheets for engraving patterns on rough surfaces, cardboard for low-power testing, and painted metal sheets for testing the accuracy and depth of the engraving.

Our pattern can be used on wood with different parameters to test the following:

- Engraving patterns and letters to test the sharpness and resolution of the engraving on the wooden sheet with different values of Speed and Power.

- Cutting circles to demonstrate cutting at various speeds and power values in each pass

- Repeat pattern with different power values to compare the engraving results when changing the power value to different levels such as 70%, 80%, 90%, and 100%

This example gives a clear picture of the machine’s capabilities in terms of accuracy, resolutin, and efficiency in engraving and cutting wood.

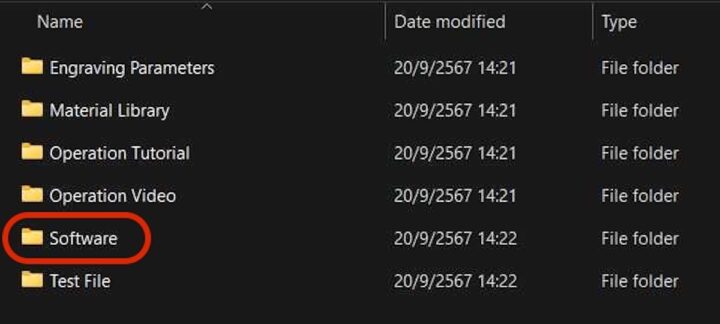

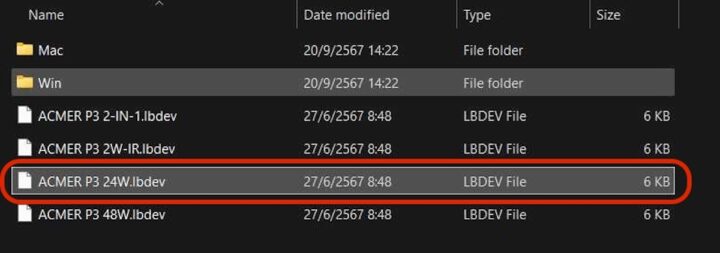

The software and user manuals for the laser engraving machine are stored on the microSD card. Supported software such as LightBurn and LaserGRBL can be downloaded and installed from the device. A card reader is also provided for people having a computer without a microSD card reader.

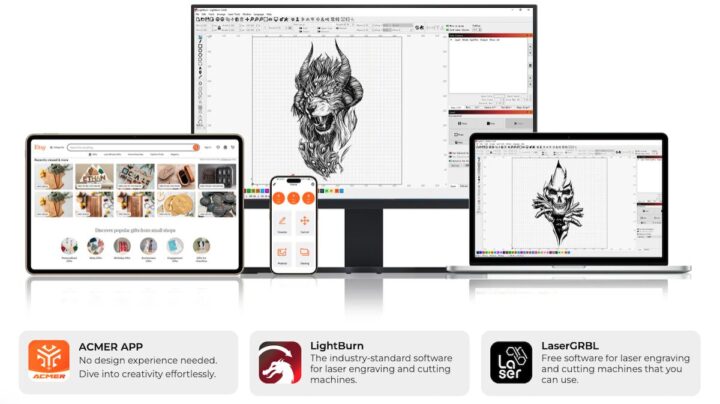

LightBurn is the standard software for designing and controlling laser engraving machines, supporting detailed parameter settings. LaserGRBL is a free, easy-to-use software, suitable for those who want to start with engraving machines. Besides the PC-based LightBurn and LserGRBL programs, the ACMER mobile app can be installed for users with no design experience allowing easy creation of engraving works via smartphones or tablets. All three programs provide flexible control and pattern design, suitable for users of all levels.

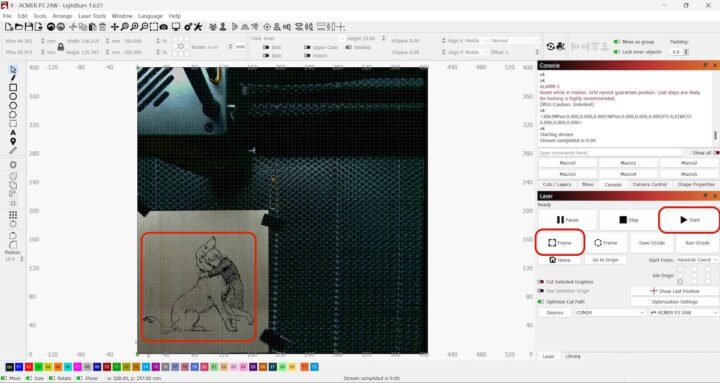

Review of the ACMER P3 48W laser engraver with LightBurn

We’ll use LightBurn for this review. Note it’s not free (as in free beer), but there’s a free 30-day trial version to allow users to try out the features before deciding to buy which we’ll use in this review. Licenses for the GCode Controller are around $40-60 USD and for the DSP Controller are around $80-120 USD. You can download the program or enter the “Software” folder on the SD card to install LightBurn-v1.6.01.

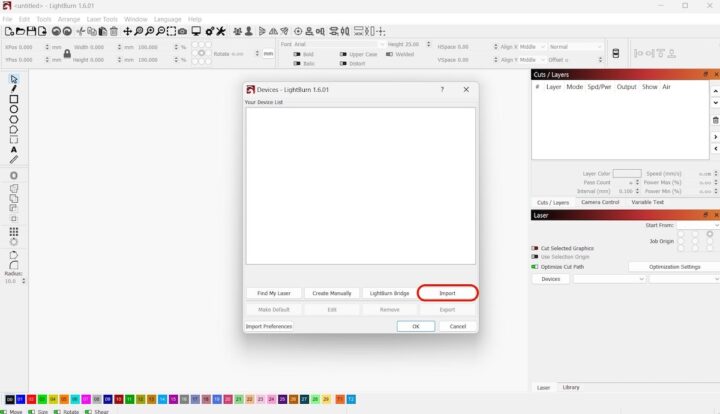

Once it’s installed, we can start the program, go to Devices, and click on Import.

Select the ACMER P3 24W.lbdev config file in the microSD card.

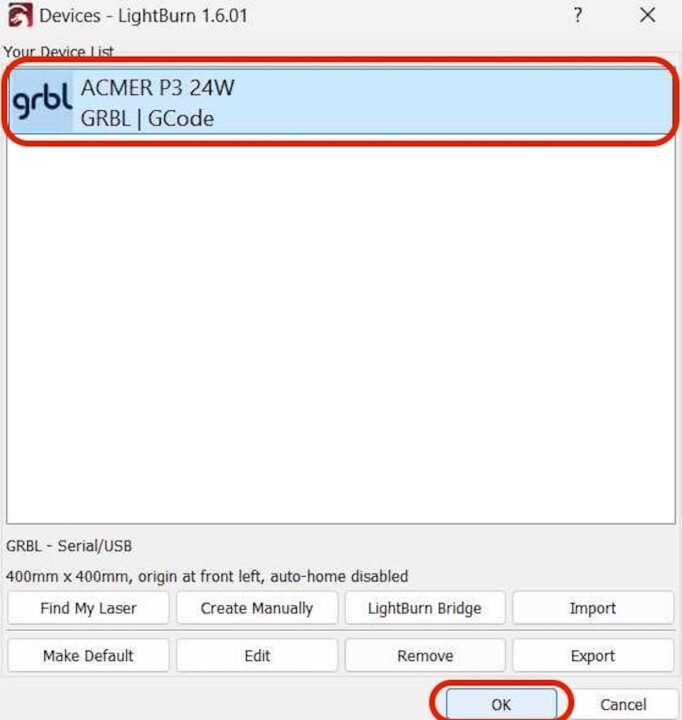

The program will show “ACMER P3 24W” in the Device List and we can click “OK”.

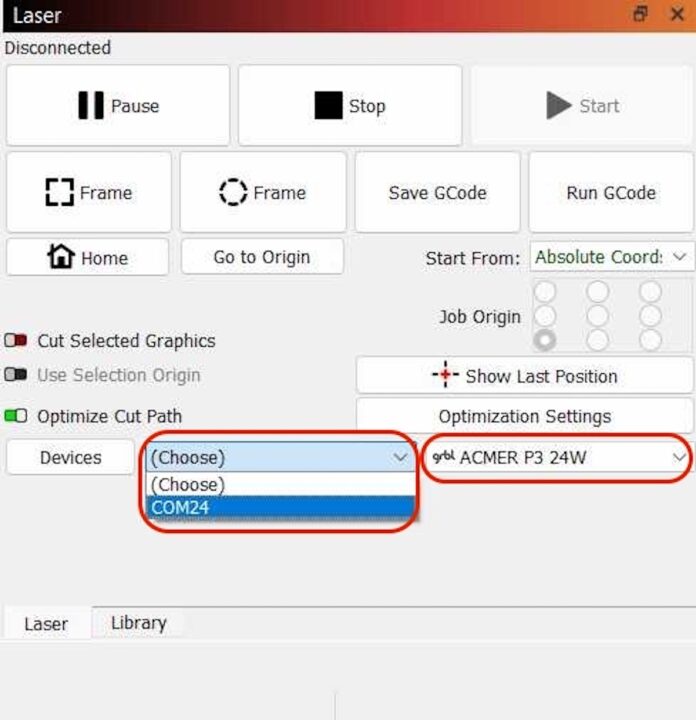

Make sure the USB cable is connected to the ACMER P3 engraving machine, then select the connection port and select the device “ACMER P3 24W”.

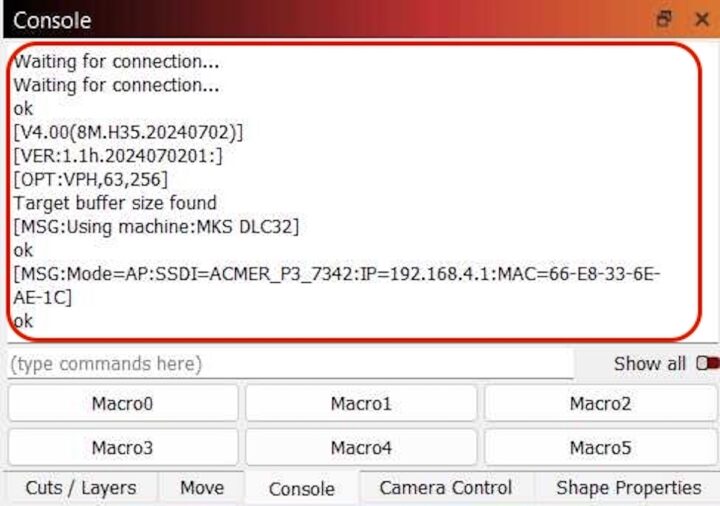

The Console window will now show a successful connection message…

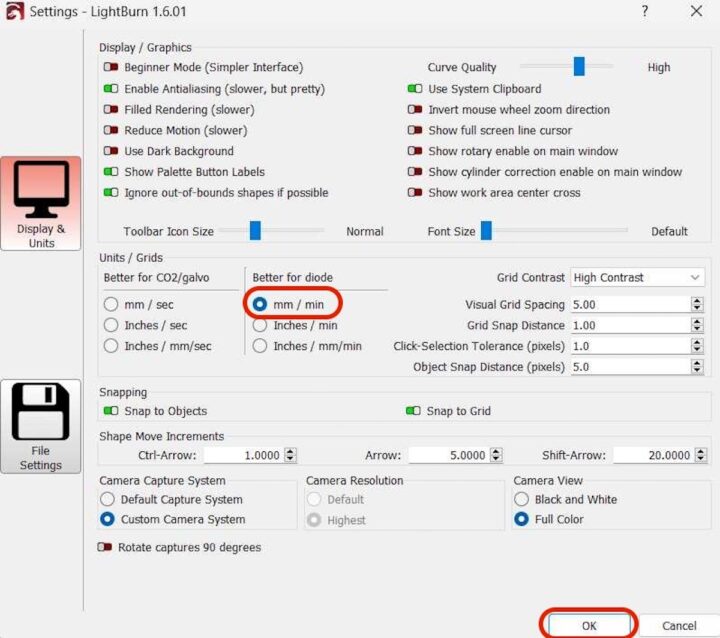

In the Settings window, select Units/Grids as mm/min in the “Better for diode” section, and click “OK”.

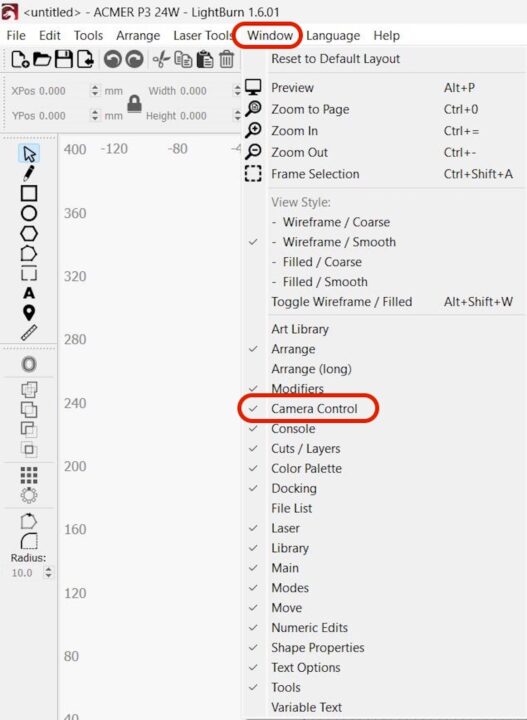

Now go to Windows->Camera Control.

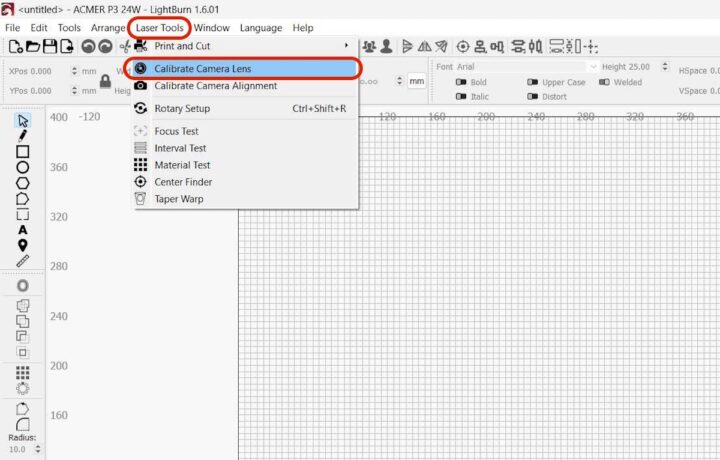

After it’s enabled, you can calibrate the camera by going to Laser Tools->Calibrate Camera Lens.

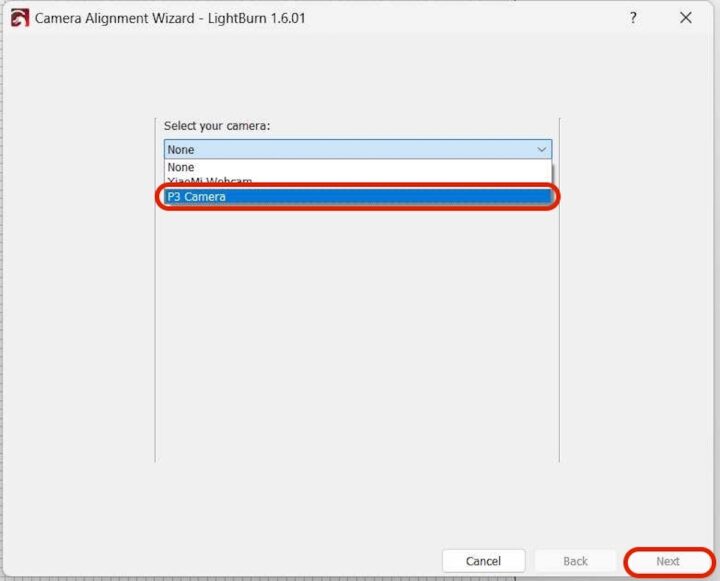

Select P3 Camera and Standard Lens in the Lens Calibration Wizard, and click “Next”.

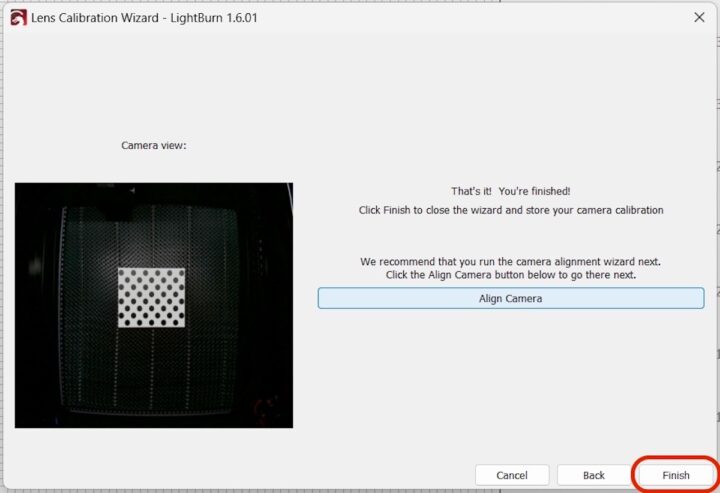

Place the camera calibration sheet in various positions, and follow the steps to complete the camera calibration process. Once done, click on the “Finish” button.

The next step is to calibrate the camera alignment. We can do that by going to Laser Tools->Calibrate Camera Alignment.

Select “Camera is over the work area, in a fixed position“.

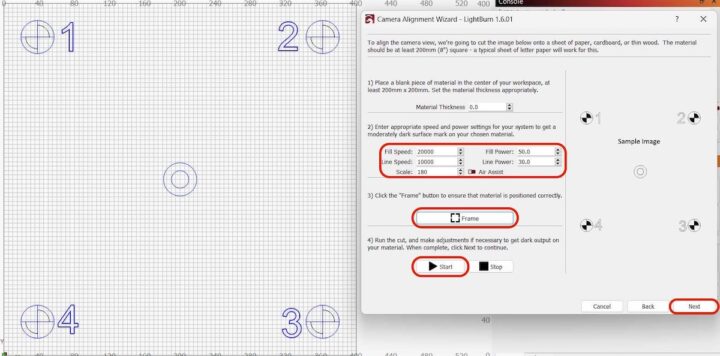

Then place all 5 wooden boards according to the positions in the image and set the settings in the program in section 2) as follows:

- Fill Speed = 20000

- Line Speed = 10000

- Scale = 180

- Fill Power = 50

- Line Power = 30

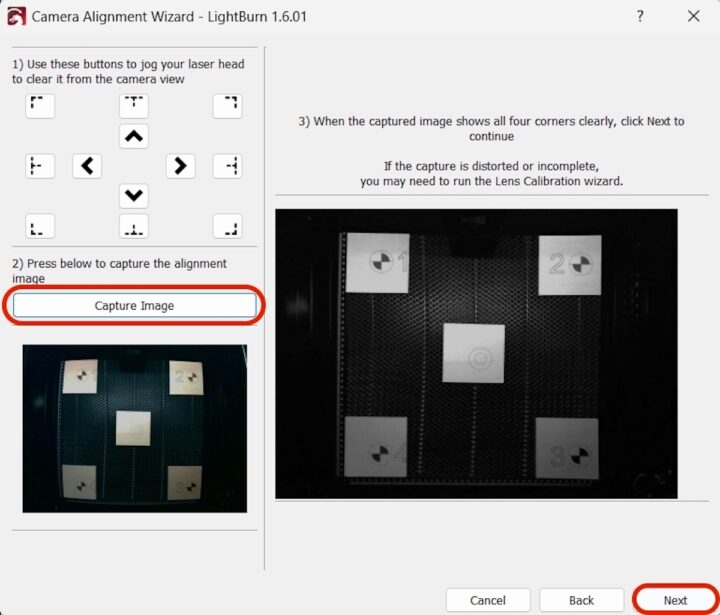

When we can see the image as shown in the picture below, we can click “Capture Image” and then “Next”.

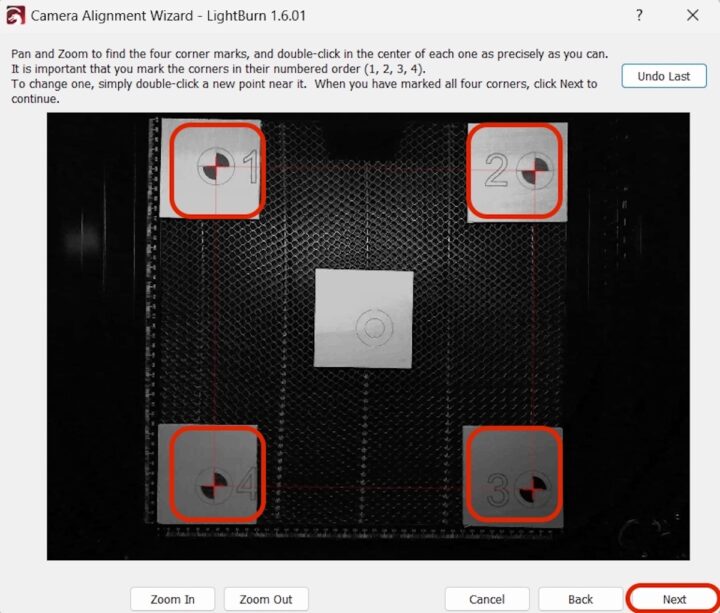

We can now adjust the position of the 4 points to align with the 4 corner intersection points as shown in the picture below. Once done, click “Next”.

The camera calibration process is now complete.

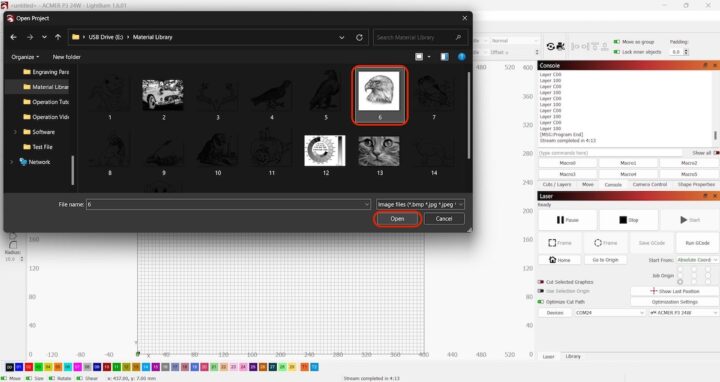

Let’s engrave a photo on a wood sample. We’ll first select the picture to be engraved (it must be a PNG file with no background). To do so, go to Open Project, select the picture, and click Open.

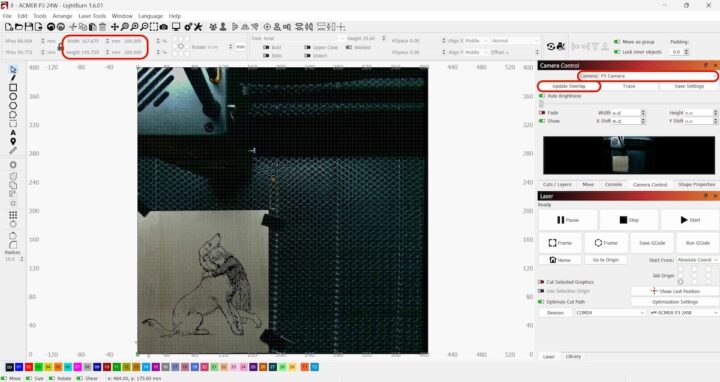

Now let’s select Update Overlay in the Camera Control section and select the carving style to be in the workpiece area.

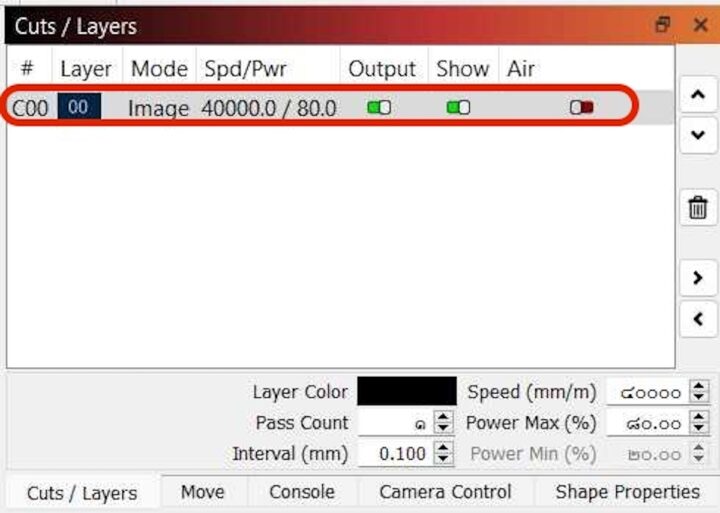

In the Cut/Layer windows, select the Mode as Image with the following settings:

- Speed = 40000 mm/min

- Power = 80 %

- Air = OFF

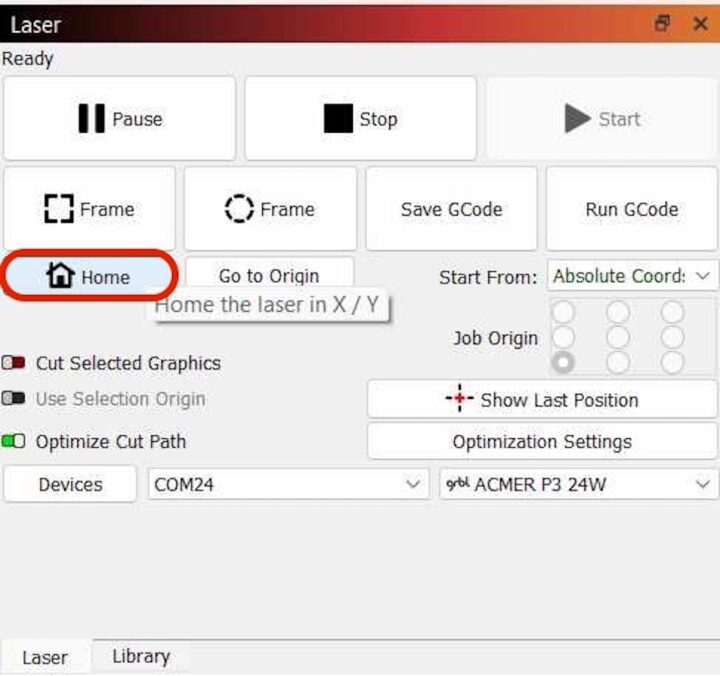

Now let’s go to the Laser section and click “Home” to “home” the laser module to the origin position.

Let’s test it by clicking the “Frame” button. You will see that the laser module will move in a square with the position to be engraved. Click “Start” to start the engraving process.

After a short time, we can see the engraving is successful and looks sharp and clear.

Time to switch to cork carving with the following settings:

- Speed = 40000 mm/min

- Power = 80 %

- Air = OFF

We then engraved CNX Software on a coated metal sheet using the following parameters

- Speed = 30000 mm/min

- Power = 100 %

- Air = OFF

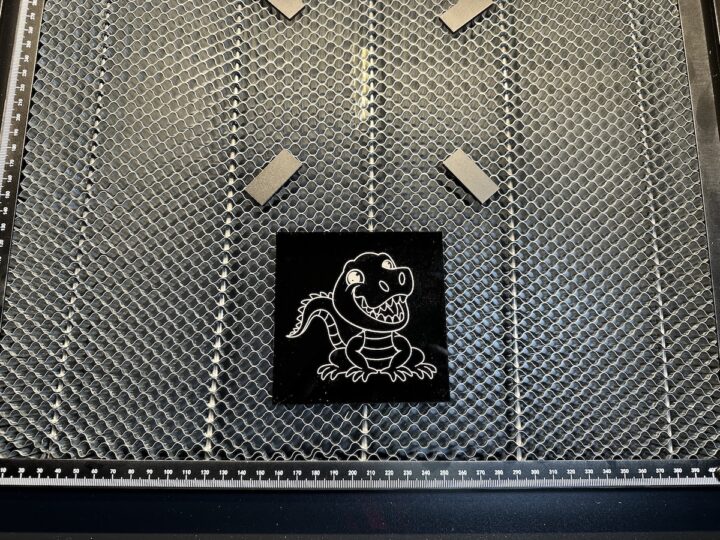

We then tested black acrylic engraving with:

- Speed = 35000 mm/min

- Power = 80 %

- Air = OFF

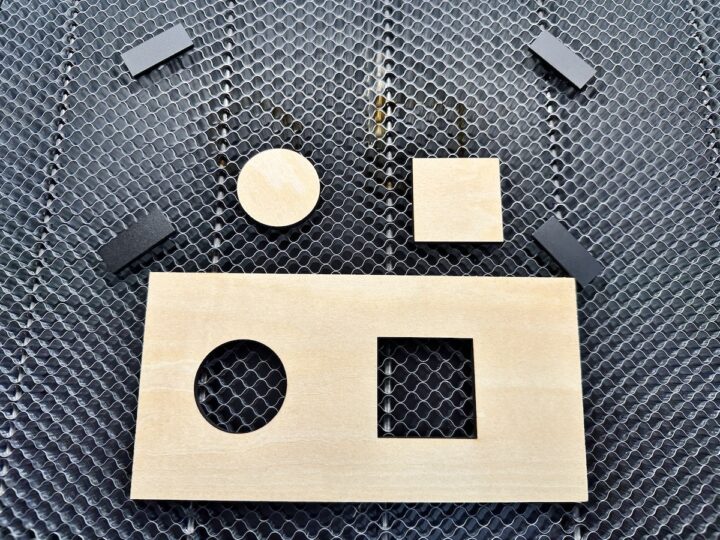

Our first cutting test used a 3 mm solid black acrylic sheet with the following parameters:

- Speed = 500 mm/min

- Power = 100 %

- Air = ON

We then tried 6mm plywood with:

- Speed = 600 mm/min

- Power = 100 %

- Air = ON

So far so good. The cuts don’t have the usual burned-out edges seen in laser engravers that lack an air assist pump.

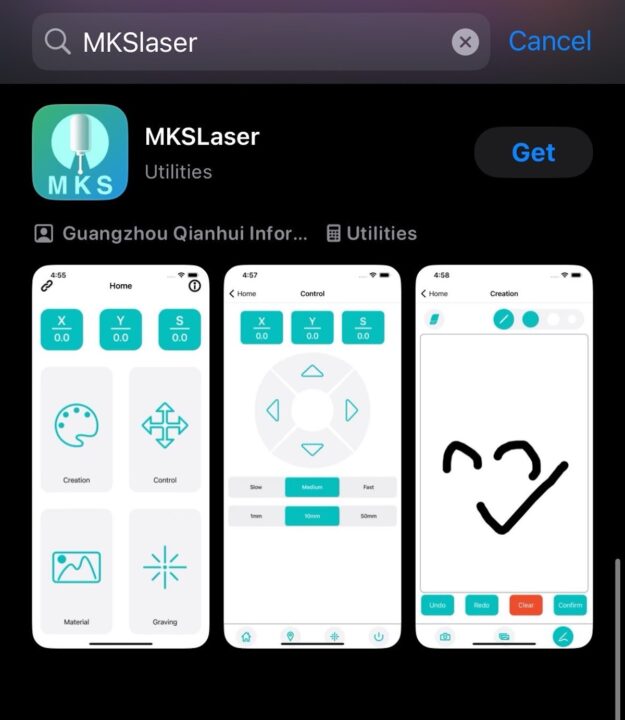

ACMER P3 48W laser engraver tested with MKSLaser mobile app

MKSLaser is an Android/iOS application used to control laser engraving machines via mobile devices over Wi-Fi or Bluetooth without relying on a computer. We can import images or work files and directly customize various patterns, including setting parameters such as speed, laser power, and operating mode in the app. It has a preview mode, and the app’s interface is user-friendly.

Once installed, we can connect to the laser engraver’s SSID, in our case, ACMER_P3_7342.

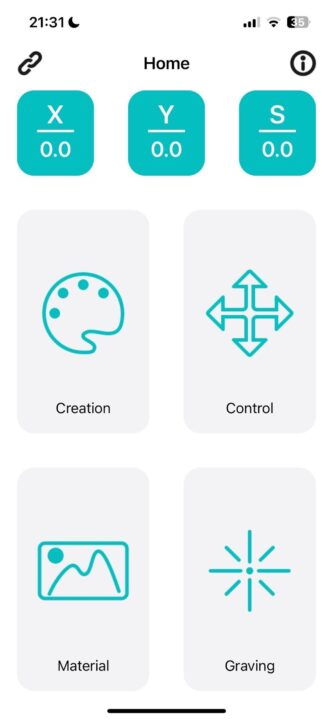

The MKSLaser app’s main menu has functions helping users control the laser engraving machine with X, Y, and S axes and four icons:

- Creation for creating and designing patterns,

- Control for the movement of the laser head

- Material for selecting samples

- Graving for starting engraving

The material section of the MKSLaser app shows a selection of shapes and patterns for engraving. There are basic shapes like squares and circles as well as pre-made patterns like a trophy, a baseball glove, a hot dog, an airplane, a car, a scooter, and a soccer ball. It is ideal for creating simple engravings without having to design them yourself.

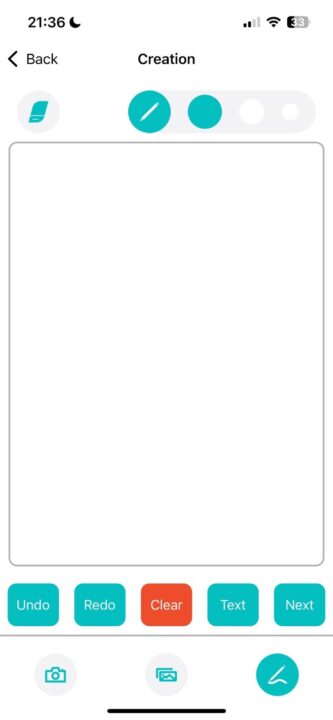

But once you’ve tested some of the predefined samples, you’ll want to go to the Creation page to use your own patterns. There are tools for drawing lines, resizing, and editing patterns such as Undo and Redo buttons to undo or redo actions, a clear button to clear the entire area, and a text button to add text. It is also possible to directly import photos or graphics from the gallery or camera through the buttons on the bottom bar.

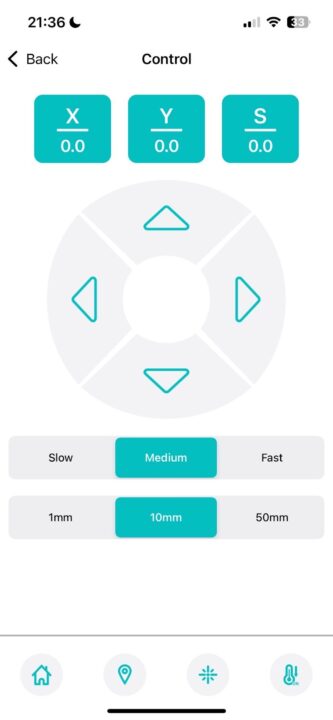

The Control section in the MKSLaser app is used to control the movement of the laser head on the X, Y, and S axes and display the current position of the laser head in millimeters. We can use the arrow keys to move the laser head in the desired direction, with options to adjust the movement speed (Slow, Medium, Fast) and the steps (1mm, 10mm, 50mm). This screen allows precise setting of the position of the laser head and is convenient for starting an engraving job.

ACMER P3 48W laser engraver video review

Conclusion

The ACMER P3 48W is a powerful laser engraver suitable for engraving and cutting a range of materials such as plywood, acrylic, leather, paper, and painted metal. The machine has a CoreXY system that provides high-precision laser head movement.

It’s compatible with popular software programs such as LightBurn and LaserGRBL and features a built-in HD camera that makes positioning and previewing patterns easy and convenient. An 8-layer protection system with automatic shutdown when the lid is opened, a key lock for safety, and more makes it safe to use in homes, offices, and schools.

The machine ships with all accessories needed for installation and maintenance such as wrenches, screwdrivers, an exhaust pipe, and a USB drive for installing software. The ACMER AP220 Smoke Air Purifier is an option for the ACMER P3 48W designed to support smoke and odor filtering during engraving and cutting. This system is supposed to reduce smoke accumulated in the work area and protect the user’s health from potentially harmful particles, but we can’t comment on that part much, since our sample had issues.

The ACMER P3 48W laser engraver is suitable for home users who need a compact, powerful, easy-to-use, and safe machine to create arts or DIY products, as well as small businesses making crafts, gifts, or producing small-scale personal products, as well as educational institutions that need to use it in the classroom or educational projects, such as teaching design or using a laser machine. It is also suitable for both beginners with no experience and professionals who need high precision and efficiency.

We would like to thank ACMER for sending the P3 48W laser engraver and ACMER AP220 Smoke Air Purifier for review. The ACMER P3 48W laser engraver can be purchased for $1,499 on the company’s website (Acmerlaser coupon lowers the price by an extra 10%), on Amazon for $1,799, or on AliExpress for $1,400 . The ACMER AP220 Smoke Air Purifier is sold for $329 on the online store, or $279 on AliExpress. We could also find it on Amazon, but it is currently out of stock.

CNXSoft: This article is a translation – with some edits – of the original review on CNX Software Thailand by Kajornsak Janjam, and edited by Suthinee Kerdkaew.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress