Many PCB vendors now provide flexible PCB manufacturing services, but Murata goes further with stretchable PCB technology that’s not only bendable but can be twisted and stretched to better fit on the body for bio-sensing and medical applications even on parts such as an elbow.

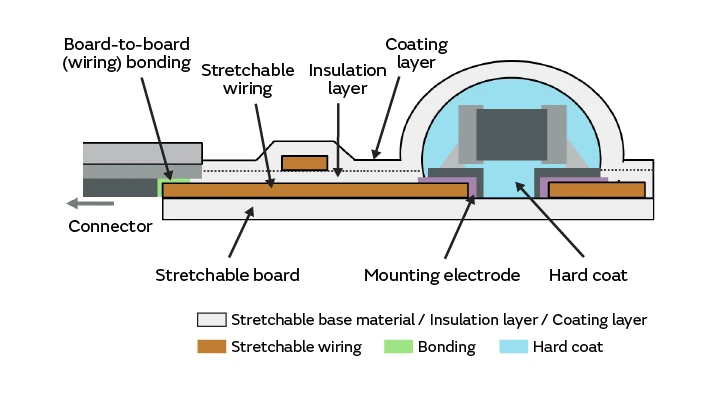

Traditional bio-monitoring sensors have some limitations. For example, they can become unstuck when the body moves, damage the delicate skin of infants and the elderly, data may be distorted due to body movement, and Murata explains “there is a risk of a decline in insulation and the occurrence of ion migration when using a thermoplastic polyurethane elastomer (TPU), known as a stretchable base material, in a high humidity environment”. The company’s stretchable printed circuits ((SPC) are supposed to solve or at least mitigate all those issues.

The technology is under development, but Murata still shared some highlights of the technology:

- Stretchable electrode printing in compliance with ANSI/AAMI EC12 (in-house test). EC12 is a standard established by the American National Standards Institute (ANSI) and the U.S. Association for the Advancement of Medical Instrumentation (AAMI) that stipulates the specifications required in disposable electrodes used when conducting electrocardiograms and other tests.

- About 100 µm per layer

- PCB tested with stretchable silver and silver chloride electrodes

- Suppresses the occurrence of ion migration, a phenomenon that causes short circuits in metal wiring, pattern wiring, and other elements formed on resin materials due to the application of a constant voltage in a high-humidity environment.

- Coating with a safe base material verified with a cytotoxicity test (in-house test based on ISO 10993)

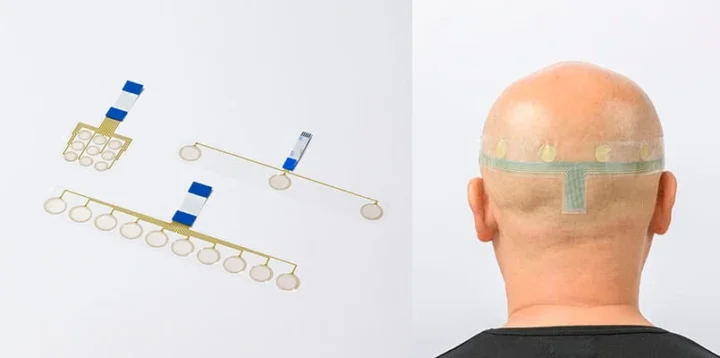

Some applications include stretchable bioelectrode array sheets for bio-potential and bioimpedance measurements such as electrocardiograms (ECGs), electroencephalograms (EEGs), and electromyographs (EMGs), active electrode sheets equipped with an amplifier near the bioelectrode, wireless stretchable wearable patches equipped with BLEs, MCUs, and coin batteries, multi-parameter measurement sheets equipped with various sensors such as thermistors and accelerometers, and shielded soft signal distribution cables.

Some applications include stretchable bioelectrode array sheets for bio-potential and bioimpedance measurements such as electrocardiograms (ECGs), electroencephalograms (EEGs), and electromyographs (EMGs), active electrode sheets equipped with an amplifier near the bioelectrode, wireless stretchable wearable patches equipped with BLEs, MCUs, and coin batteries, multi-parameter measurement sheets equipped with various sensors such as thermistors and accelerometers, and shielded soft signal distribution cables.

Murata did not provide a timeline for the stretchable printed circuit services, but the company shares that they will be able to design and manufacture interface modules between the human body and medical devices, jointly develop custom products, and provide local support. But they can NOT help customers design medical devices, implement final productization and conduct inspections, conduct clinical trials, and obtain approval as medical devices. More details can be found on Murata’s website and the video below is worth a watch as stretchable PCBs can be twisted and stretched by more than I initially thought.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress