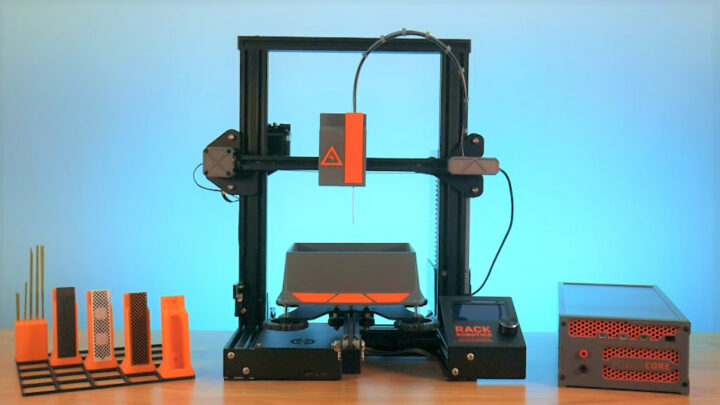

Rack Robotics’ Powercore is an Electrical Discharge Machining (EDM) kit that converts your existing 3D printer (or CNC router) into a machine capable of cutting high-precision and detailed metal parts.

We’ve already seen 2-in-1 3D printers and laser engravers such as the Creality Ender 3 S1 Pro, but while this type of machine can usually cut plywood or engrave stainless steel, the laser is not powerful enough to cut through aluminum. The Powercore EDM kit changes that by enabling the cutting of aluminum parts up to 4mm thick, although aluminum sheets that are 1mm or thinner are recommended.

But before we get into Powercore details, what is Electrical Discharge Machining exactly? Engineers Edge explains:

Electrical Discharge Machining, EDM is one of the most accurate manufacturing processes available for creating complex or simple shapes and geometries within parts and assemblies. EDM works by eroding material in the path of electrical discharges that form an arc between an electrode tool and the work piece.

…

The EDM system consists of a shaped tool or wire electrode, and the part. The part is connected to a power supply. Sometimes to create a potential difference between the work piece and tool, the work piece is immersed in a dielectric (electrically non conducting fluid) which is circulated to flush away debris

The Powercore kit is comprised of the following items:

- Powercore EDM power supply with Raspberry Pi Pico, ACS12 current sensor, multiple internal temperature sensors, and 8 exposed GPIO pins.

- Power cable

- Electrode Wire Set

- Machining enable cable

- 2x Linear Wago connectors

- 10x 1/16″ brass electrodes

- 10x 3″ square aluminum stock material

- 60x magnets for creating tools and workholding

The Powercore is open-source hardware and I understand the hardware design files, 3D files, and Raspberry Pi Pico firmware will be released after the crowdfunding campaign ends.

I recommend you watch the video embedded below to better understand how the kit is installed and how the cutting process works. The aluminum parts are immersed in distilled water as a dielectric is required for the EDM process. Files for the kit can be generated in programs such as Fusion360 where you can export a DXF and then import it into the LaserWeb4 program to generate milling toolpaths.

Rack Robotics have raised over 180,000 dollars for the Powercore EDM kit on Kickstarter so far with 4 days to go. Since the $299 early bird pledges are all gone, a $399 pledge (plus $29 for shipping) is now required to get the kit. The company only ships to the United States at this time, and deliveries are scheduled to start in August 2023.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

USA only 🙁

> USA only

For now. If the design turns out to be any good, I’m sure clones will pop up quickly.

I think they were right to limit the availability at this stage; it seems that shipping stuff out of the US is a lot harder than shipping it in (at least when there would likely be only a few items to any particular country). They’ll have enough problems going into production and even though the KS has been very successful I doubt there’s enough money involved to hire the kind of international shipping specialist service that could work through those problems. Maybe if the product turns out to be popular after the KS they would look into it (though by then lower-cost clones would already have become available).

Note: I am a backer of the KS, so my view is biased.

I’m excited by the possibilities of a lower-cost EDM power supply. Their focus on a fast cutter for thin metal is intriguing, but I’m more interested in trying to use it for a more traditional sinker or even wire type. It’s low powered for such roles, but that should only mean a slower rate (maybe?). Slower than conventional supplies, but a lot cheaper: I can live with that.

Besides, the idea of using what is essentially a 3d printer bed-heater to make cheap PCB power resistors just seems cool to me. Maybe that’s common practice, but its the first time I’ve seen it.

EDM machines in general have a reputation as a fire hazard. I wonder it they have a fix for this and if one should declare it on the house insurance?

Correct me if I’m wrong. They plan to use EDM, which uses a bunch of high voltage electric discharges per second, on a regular 3d printer with no shielding practically anywhere?? Electric discharges are a horrible source of EMI. Ain’t no way this is going to work for everyone