3D printing can be time-consuming and challenging, and even today, it’s still not as easy as using a photocopier, but the team at Bambu Lab has taken it upon itself to make a better, easier-to-use 3D printer with the X1 color 3D printer combining LIDAR and AI technology to level the bed, calibrate the prints, and detect anomalies.

The Bambu Lab X1 3D printer supports up to 16 colors, is making removing support easier with snap-away material or dissolvable filament, can handle PC and PA-CF filaments beyond the traditional PLA and PETG filaments, manage up to 500 mm/s prints, and provides better prints with features such as active vibration compensation. Oh, and you don’t need to assemble it, since it comes fully assembled and ready to use out of the box.

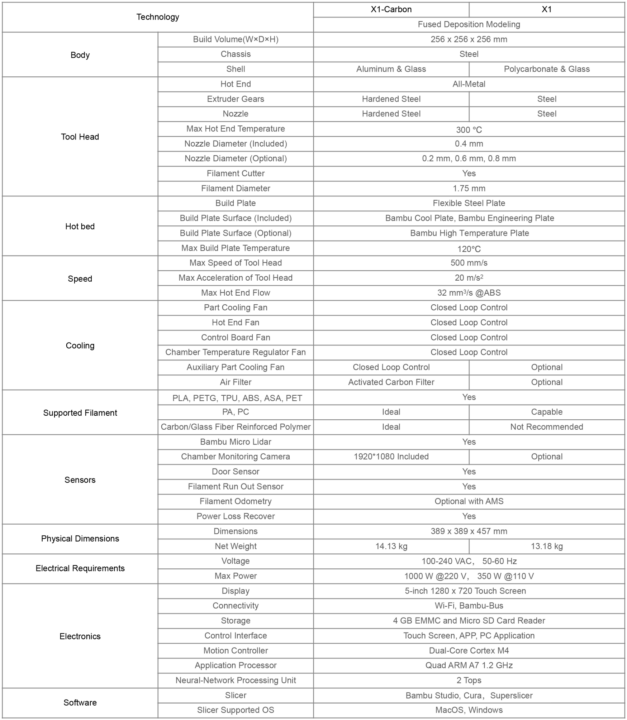

There are two models of the 3D Printer with X1 and X1 Carbon with the latter featuring more sturdy materials like aluminum and hardened steel, and additional features such as an extra auxiliary fan with closed-loop control, an air filter, and a monitoring camera. The X1 Carbon can also provide better printing for PA and PC filament, and it’s the only model that can properly handle carbon/glass fiber reinforced polymer filaments.

The 3D printer controller features a dual-core Cortex-M4 microcontroller, while the AI/Linux part runs on a quad-core Cortex-A7 processor @ 1.2 GHz with a 2 TOPS NPU, which could be a Rockchip RV1126 SoC, although the processor is rated at up to 1.5 GHz. The company will provide its own Bambu Studio slicer software for Windows and macOS, but the printer is also compatible with Cura, Superslider, and others generating G-code. The company will make some parts of the software open-source, but keep the hardware and firmware closed-source as explained in a blog post.

Some of the samples are quite impressive with the castle shown below especially standing out.

But it’s also possible to make simpler objects like this nice-looking color enclosure for Raspberry Pi 4.

The X1 printer is also fast with the Benchy sample printed in 16 minutes and 30 seconds with a 0.1mm layer height (TBC).

For reference, Karl’s attempt at speed printing with Benchy resulted in a 37 minutes print with a 0.3mm layer using Longer LK5 Pro 3D printer. The company admits the 3D printer is still not quite as easy to use as a consumer device, but they’ve gotten closer to their goal:

Do all those smart features completely eliminate tinkering and tuning? No.

Is this printer as reliable as a photo copier? No.

Is this the printer you guys dream of? Not there yet.

Bambu Lab has launched the X1 and X1 Carbon 3D printers on Kickstarter with so far over 6.5 million dollars raised from about 5,200 backers. There are only about 5 days left, and all early bird rewards are gone, but you can still pledge for the X1 and X1 Carbon for respectively $800 and $1,200. The retail prices (MSRP) are expected to be $999 and $1,449. Shipping adds about $27 to China and Hong Kong, but shipping to Europe and the US goes up to about $135, and double that for some other destinations like Singapore or Thailand. Crowdfunded 3D printers have a rather poor history with a high failure rate, but it looks like the Carbon X1 is already manufactured or soon will be with rewards expected to ship in July or August 2022, so the risks may be limited.

Thanks to Karl for the tip.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

Interesting, but I have a good deal of skepticism about it in the real world.

Look like the key team is all ex-DJI, so they have a bit of track record, but not in 3D printing.

Pricing is extremely aggressive for that they are delivering (welded frame, LIDAR, multi-material unit, etc. And “AI” claims always make me skeptical. Maybe they can deliver a top quality unit at this price point using their DJI experience, but maybe not; it does seem like they have a lot of overhead (claimed size is 150 people, and mostly in engineering).

My guess is that the printer is delivered, but doesn’t live up to the hype. This based on a number of Kickstarters from existing 3D printer companies that, based on the comments after delivery, didn’t deliver on the campaign promises.

The hardened steel nozzle is hardened to 50 HRC, while the E3D Nozzle X uses 68 HRC tool steel and 73 HRC nickel plating. Also note that the hardened steel nozzles aren’t considered the best for regular materials because the thermal conductivity is less (which is why I’m using a 0.4mm tungsten carbide nozzle as my main nozzle).

As far as speed goes, I wonder how fast it will work with common materials, such as random PLA from Amazon/AliExpress/etc, or flexy materials. Sure, it’s great to move at 500mm/sec when not printing, but can it really print flexy at 500mm/sec?

The multi-material unit appears similar to the MMU, with purge materials ejected out (instead of onto a tower on the build plate, or used as in-fill). This approach has disadvantages such as massive waste of material, hard to get reliable (e.g. MMU revisions), and hard to mix different material types. Besides the Prusa XL, it looks like there’s a lot of open source interest in the tool changer approach (e.g. using E3D or BlackBox).

That said, there are definitely a lot of good ideas, such as automatic calibration using LIDAR, and measuring the height of the print head.

tfb, you don’t know what funding they have. A lot of companies use Kickstarter more as a marketing vehicle than actually funding one. Would be kind of interesting to know what is behind that company.

Either way… Smart people

You missed my point: it’s harder to make a profit when you have a lot of people to pay. If they’ve really paid 150 people for 2 years, that’s a lot of money that needs to be paid back from the price of the printer. And even the non-KS price, if it’s even ever sold at that price, is pretty aggressive.

Yes, they may be smart people, but 3D printing is a very different domain than drones, so there’s a big learning curve. For example, I wonder how well the linear motion components will handle 500mm/sec velocities over thousands of hours.

It’ll be interesting to see how well the printer lives up to the hype – I’m going to be checking the KS comments periodically.