When I think about welding machines, I imagine fairly large units, protective gloves and masks, plus sparks coming out of the welding process when two metal parts are melted together.

So when I saw a small “portable DIY mini spot welder machine” going for $25 on Banggood[update: or just under $20 shipped on Aliexpress], I thought to myself: “what is THAT”? It turns out it’s made for welding jobs with thin nickel-plated steel strips such as the ones that can be found attached to 18650 batteries, or full battery packs.

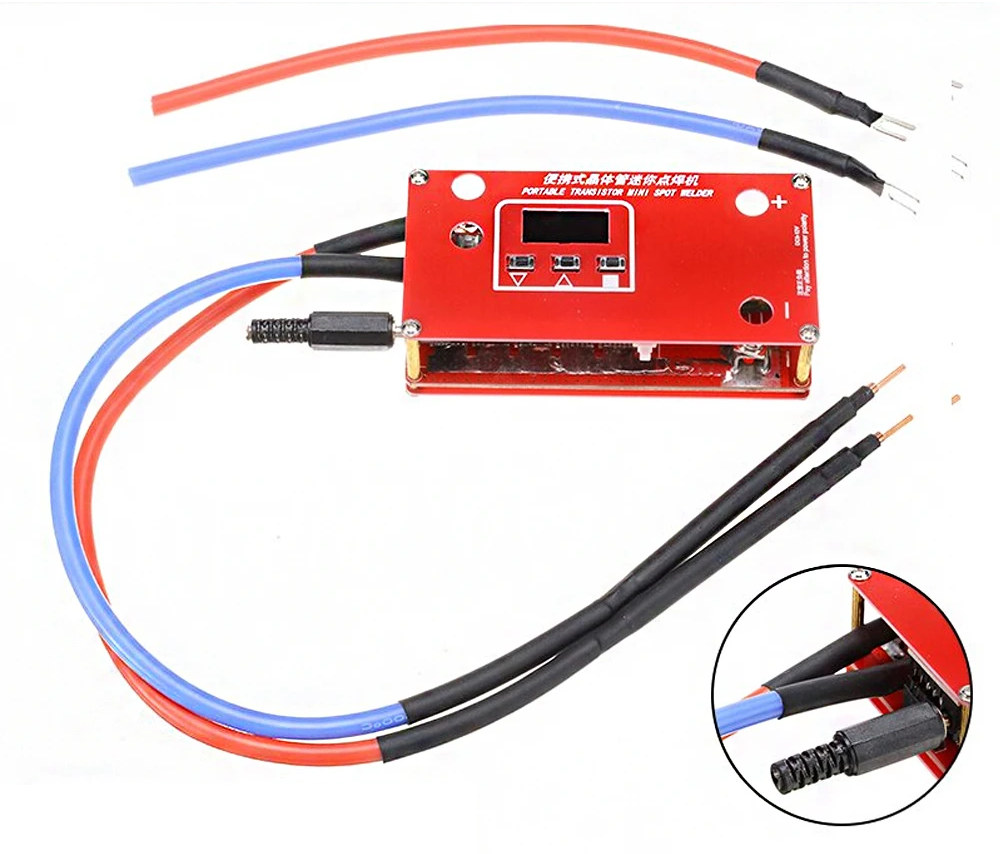

Mini spot welder specifications:

- Controlled with by unnamed MCU

- Display – LCD with welding parameters:

- WELD ENERGY – 01-99 adjustable by up and down keys

- INPUT – Display input power voltage

- WELD WAY – Manual / Auto (adjustable with “square label” button)

- Based on 5x 300A MOSFETs

- 30cm 10AWG cables for welding pens

- 25V 10000uF high-frequency low-resistance capacitor to increase welding stability.

- Misc – Power switch, buzzer

- Power Supply – 12V via DC jack or car/lithium batteries through 20cm 10AWG input cables

The kit is designed for welding nickel-plated steel strips from 0.1mm to 0.15mm and includes the controller, two welding pens, two power input cables, and a black plug. The best way to understand how it works is to check a demo on YouTube. The one below shows the user welding a metal strip to a 18650 battery.

Note the reviewer above may not have welded the strip in an optimal manner, as one commenter explains:

The two pens must be placed vertically, perpendicular to the plate, on the surface, because then it transfers the strongest energy due to the size of the surface! This is also written by the Chinese manufacturer! Regards from Hungary, spot welder.

It also feels like an electric shock hazard, but I suppose people doing will be extra careful. It’s also sold on Amazon, and some of the user reviews there indicate it can easily be destroyed by short circuit:

After receiving this spot welder i connected it and tried a few spot welds. Device worked correctly at level 20 and level 30. I then set it to level 40 and tried another weld. As soon as i touched the probes to the metal there was a huge explosive spark. Now thats all it does. It appears that the device now provides a direct short circuit to the battery. Apparently,either the mosfets have shorted out or the control circuit is stuck in a fully on state.

Another one reported a similar issue on Banggood,

Worked for 2 spots, third spot, stuck on melted strip. Didn’t shut off and started smoking, disconnected power. Was on auto mode with power set at 20, running off of a 12 volt 7 amp hr battery. Now it pumps full amps continuously, touch 1 prone to metal strip then when you touch the second probe it throws a huge spark and melts / burns through strip / blows a hole right through. In safe to have around in this condition.

but apparently, there are solutions:

The problem is the MOSFETs are not balanced and the power goes through one and overloads, this circuit needs protection,some solutions on YouTube.

This looks to be due to a voltage drop and can be solved with a 470-1000uF 16V capacitor as explained in the video below.

He also explains that if you blow up your MOSFET they can be replaced with Infineon IRL40SC228CT MOSFETs (0.5mOhm 1440A pulsed).

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

I just came here to say, I had one, it blew up after a few welds. LOL.

Some reported the same problem. Did you try the capacitor workaround?

It’s amazing to see that there are people downvoting the article’s author when he asks a question whose response interests most readers!

I considered a few times buying one of these in the past, but always suspected they were pure garbage. Seeing that they didn’t even protect the pulse generator against the power loss that happens during the short circuit definitely convinces me that design was as good as QA :-/

If you use a source with adequate current discharge capacity rating, the voltage will not sag and the MOSFETS will remain fully turned on and the MOSFETS will remain fully conducting during the weld pulse time…..even with the hold up capacitor mod, if your source current capacity rating is not adequate, the quality of the welds could like suffer….the problem is not the design, it’s operator headspace….Like on an M2: if you don’t bother to set it right, it can blow up in your face……literally

Wow nice find, thanks for adding the fix link.

Awesome! Might pick one up and do the recommended fixes. For a few cells a year, should be good enough.

I just make enclosures with bolts and nuts for mine. Not that compact, but removable at least.

I had a look at these many devices, they all use the same Infineon MOSFET (4N04) which stands 300A continuous, bond-wire limited while the chip supports 700A continuous. For me this definitely indicates that there could be only two causes for some chips turning to short-circuit: either there’s too high a reverse-voltage spike in inductive wires that instantly kills them, or that indeed, the poor control on the gate doesn’t allow the current to flow through at minimal Rdson and that this kills them. Otherwise, if it was just a matter of too large current the MOSFETs should fail open after melting their internal wires. Thus it’s very likely that the capacitor trick will work.

In addition there are other models for the same price, some with up to 12 MOSFETs and a power supply capacitor. None of them uses the onboard capacitor as a discharge capacitor it seems. All of them rely on the battery’s low internal resistance or on a supercap. As such, I strongly suspect you picked the worst design there, despite looking cool 🙂

Do you have any recommendations?

I didn’t test any of them but was attracted by the 12-mosfet one which looks well designed: https://www.ebay.com/itm/DIY-12V-18650-Battery-Energy-Spot-Storage-Welder-PCB-Circuit-Board-12MOS-Tube/313260005572? It supports both supercaps and batteries, uses potentiometers to adjust the settings once for all, and has a charging circuit for the supercaps. Given that it’s designed to work on low voltage (5V), I think you could use one or two high-discharge lipo batteries commonly found for RC planes/boats/cars. Probably that adding a few low-voltage low-ESR high-capacity capacitors in parallel could even allow to keep a single battery.

Just put a NTC on the gate of each mosfet to lower gate voltage on the first heating mosfet

If a mosfet starts to heat, it’s already too late. Think of it like a hardware switch, you never want it to make half a contact or it will instantly fuse. Here with such high-current devices it’s the same. If the gate is not fully turned on and Rdson is just 10 mOhms, at 100A the device will have to dissipate 100 Watt. You don’t have many opportunities to be wrong there before frying it. This is also one benefit of having many devices in parallel, it divides the current by the number of devices, hence the power per device by the square of the number of devices. I.e. with 12 MOSFETs each of them dissipates 1/144 of the total power.

Wow a lot of smart people here in the comments! Im here to say the real.smart thing is to buy a kWeld if you want to make a high power battery safety.

Bewere, there is a new version without the diode, so fix mentioned will have to be modified!

I think the diode is still there but it moved to the bottom board next to the big cap

Not sure if still needed, but for peace of mind i added a cap on the input connector (right side on the display pcb). See video for the pinout, written on the pcb.

I did a succesfull weld with a Zipo 60c 5000mah 3s LIPO pack with 20 units on two small peaces of 0.1*6mm.

a small hart attack later because of the sparks haha

I’m running one with all the mods and a few of my own and it is awesome. Welds on level 4 like a beast. Been making my own ebike batteries and they have been going strong for years….

Apparently it when you use too small a battery, and it can’t get a large enough current burst to switch the mosfets fast enough, and it burns them out. A MOSFET only generates heat/dissipates energy internally when it’s in the process of switching, so if the current can’t push it over fast enough, it burns through the gate junction insulator. The one I received gives a warning about using those little sealed lead acid batteries. They have very little current capability, and are meant for a long low current draw. You need a battery with 30S to 50S current supply capability for these to work right and not burn out. Use a car battery, maybe a larger lawn mower battery or a good sized Lithium Ion pack for an airplane/ RC car/Quad Copter.