Breadboards are mostly used to experiment and quickly prototype circuits before either moving the said circuit to a perfboard or designing your own PCB. But if you ever need to transport your messily wired breadboard, let alone used it outdoors, you’d need a case.

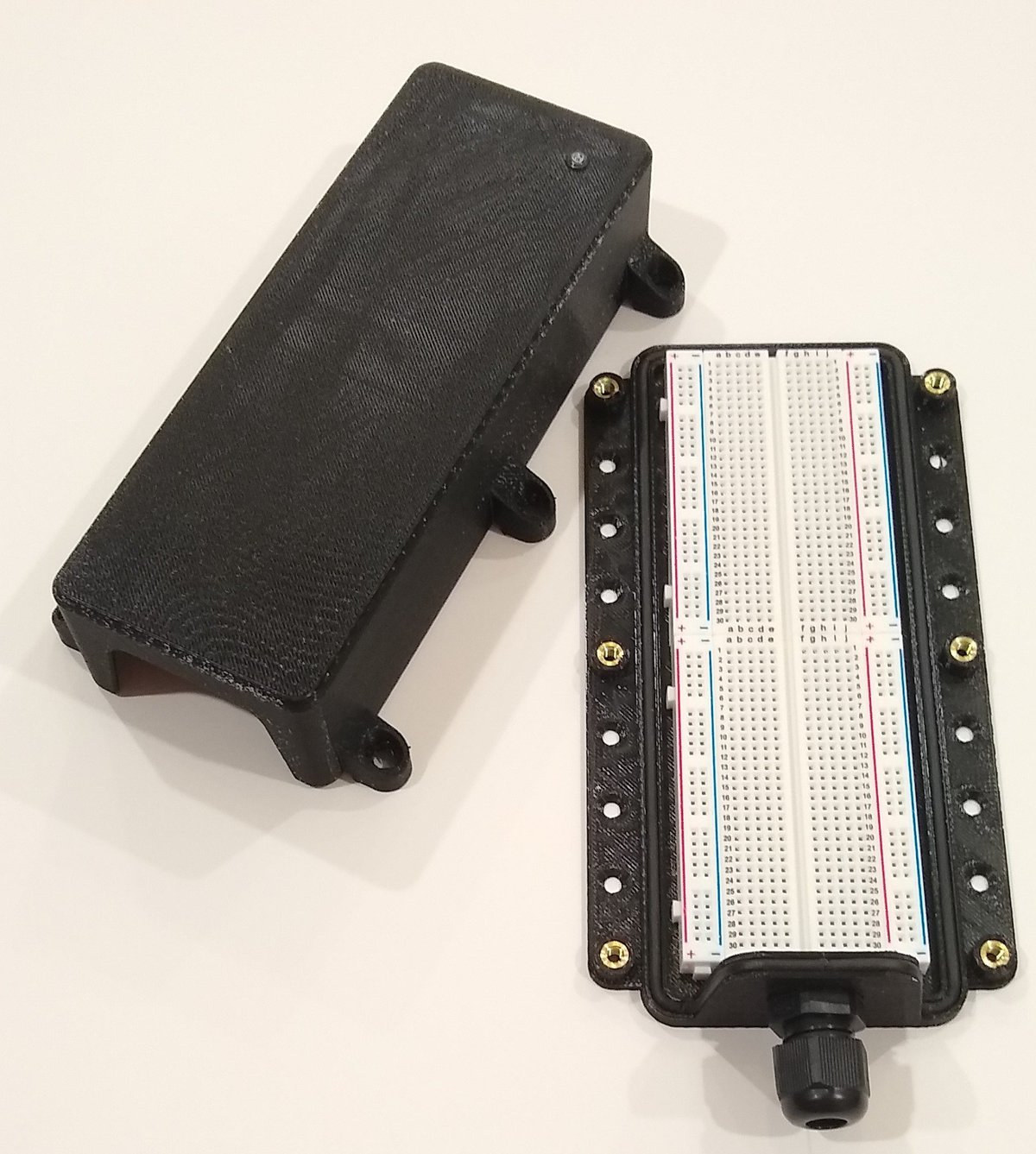

That’s exactly what Circuit Armour has built with Breadbox Double, a weatherproof breadboard enclosure designed to house two standard 1/2 sized breadboards.

The Breadbox Double enclosure is 3D-printed with ABS, features a rubber foam seal between the base and cover to create a dust-and-waterproof seal, a waterproof connector for the wires, as well as a tiny lens that allows an LED to be viewed from the outside.

The enclosure can be mounted to a wall, tree, planks, etc.. thanks to 12 mounting holes on the side of the enclosure. Once installed, you can still loosen the screws and remove the top cover to make any modifications or repair to the circuit.

Circuit Armour decided to create its own breadboard enclosure because off-the-shelf cases would not be of the right-size, require time-consuming modifications, and maybe be hard to open after installation.

Breadbox Double enclosure is sold on Tindie for $29.99. If you browse Circuit Armour Tindie shop, you’ll also find Breadbox case for a single breadboard, and Perfbox to house one 1/2 sized Adafruit Perf board.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

I don’t know why, but the idea of using a breadboard outside under a protective enclosure makes me think about an artist painting under an umbrella on a rainy day 🙂

There could be occasional situations where it would be nice to be able to protect a breadboard for a few days during an experiment, but quite frankly in this case, the good old plastic bag does the job as well.

Breadboards have too bad contacts to withstand wind an temperature variations over several days without the circuit being parasited by contact moves. And if you can’t make a PCB and want your circuit to become definitive, I think that spreading some hot glue over the components on the board will do the job fine enough at a much lower cost. But I may be wrong.

My first impression seeing this was you’d stick it outside for a day or two, the readings would stop and when you go and get it all of your components would be rattling around inside it.

Good for prototyping but I’m not sure if it will be reliable for weeks or months of operation.