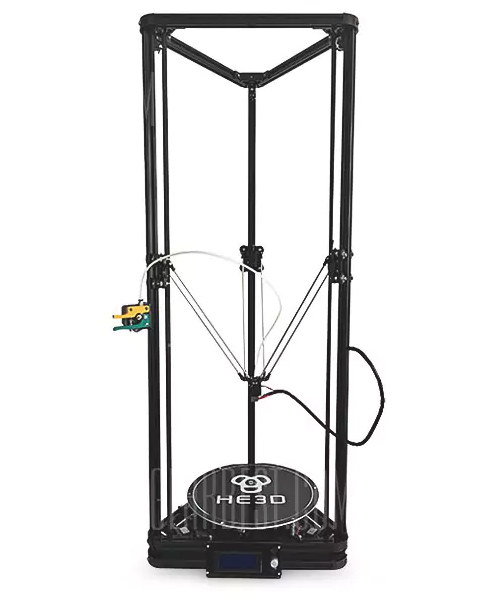

Hello Karl here again with another 3D printer review. Today we are looking at an HE3D K280. I saw the brand for the first time on Gearbest a couple months ago and asked for it to review. I never heard of this brand before and have been wanting to review a delta style printer. In my case, I should have been careful what I asked for. It took me quite some time to get it to print utilizing the whole print bed. I experienced several challenges and after defeating them I enjoy this printer quite a bit. Delta style printers mesmerize me with the movements that they make and all the math that goes into moving the extruder in the X, Y and Z. Regular Cartesian printers are rather simple in this respect.

- Build Volume – 280×600 mm

- Heated bed

- No Parts cooling

- 2020 aluminum and all injected molded parts except effector

- Bowden Style

- 24V system

HE3D K280 Build

Building a delta printer I found out is quite a bit easier to build than a Cartesian printer. The instructions for this kit are not the greatest. I followed the K200 Youtube videos for the majority of the build. I utilized the printed instructions that came with the printer and I also used the Facebook group. I wish instructions were all in one place but I was able to work through it. I contacted the HE3D Facebook representative and found him extremely helpful. I had about 6 hours build time.

I really liked that it came with some important spares/piece parts. Extra nozzles from .2 to .5 came with the kit. Extra heater block. Extra sensor for probing the bed.

HE3D Firmware

I hate to admit how much time I spent trying trying to calibrate this printer with the stock repetier firmware. I worked every night after the kids went to bed trying to calibrate for over a week. For giggles, I started compiling Marlin and I worked through all the configs, and if you use Marlin firmware you can go from build to printing in about 10 minutes with calibration. Here is a copy of Marlin Bugfix Config. Clone the Bugfix Branch and replace the 2 config files in the marlin directory. This branch is in active development so if an error occurs you might need to compare my configs with generic delta in the example configurations directory. I use Beyond Compare for this task.

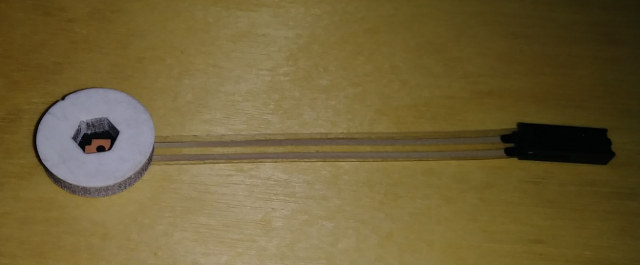

One feature I like is the sensor that is included. It fits over the hot end and it is used for calibrating. When pressure is applied it closes a contact.

This sensor is used to calibrate the machine. While building I made sure everything was as square and as tight as possible. I pushed the endstops for the three towers against the top bracing. I also leveled the bed with a speed level.

Once the firmware is flashed, I connected the sensor from above to the pins shown in the manual and placed over the nozzle. I went to Delta Calibration under Prepare in the menu. And let it do its thing. It probes the bed and several points around the perimeter of the bed then homes then does it over and over up to 10 times. At this point all I needed to do is set the Z offset, and save the configuration to EEPROM. In the marlin firmware, I defaulted the offset to -.15 but as I ran through testing -.3 works just about every time for my sensor.

If you make a change and flash firmware again please go into the menu and have it restore failsafe. That was another pain in my side realizing some changes that I made were not taking affect.

After this, I had very successful prints and the nozzle was not digging into the bed near the perimeter.

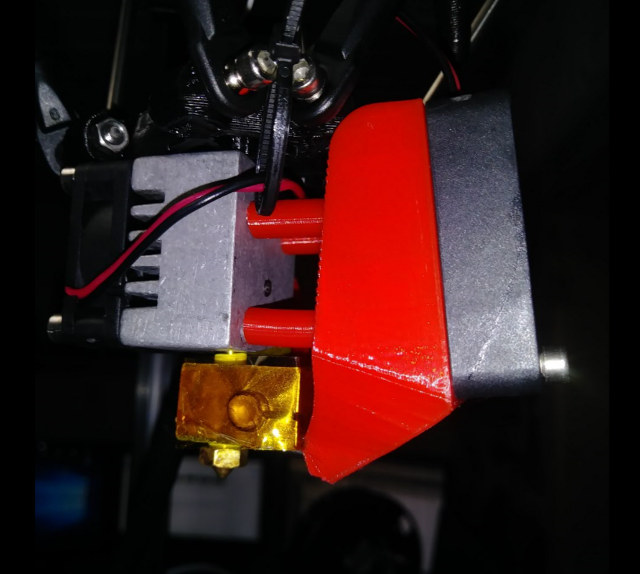

Please note you must insulate your heat block with at least some Kapton tape or run the chance of heating error if using a parts cooler.

Bed

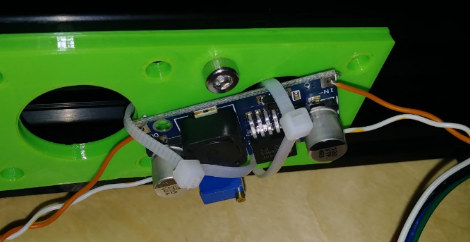

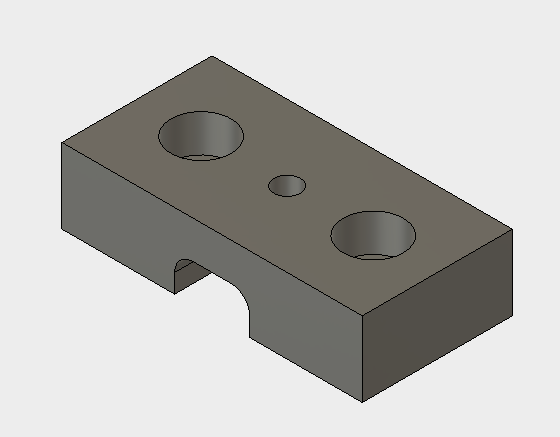

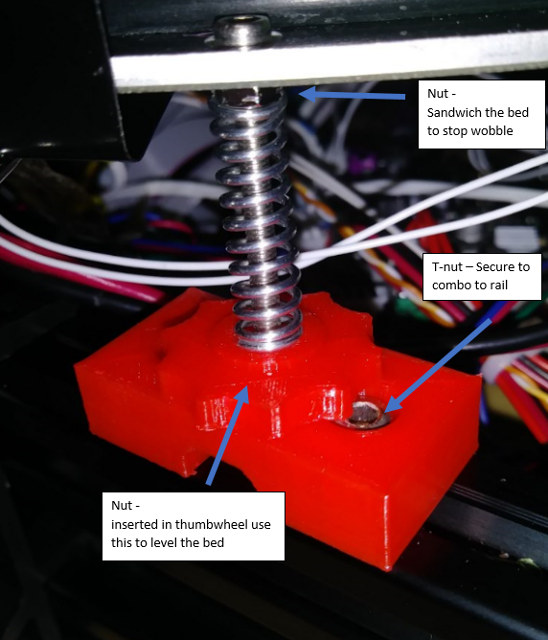

I did not like the bed mounting system that came with it. If you needed to get to the board it meant unmounting the bed and recalibrating the bed. So I designed some simple removable mounts. 3 are needed. They can be found here on Thingiverse. I put everything together like the picture below then place on 2020 and line everything up. Then tighten the t-nuts. After this I was able to pop the bed off with no tools and get underneath without worrying about calibration each time.

Parts Cooling

The K280 did not come with a parts cooler and it is a 24v system. A while ago purchased several 40mm fans and radial fans off of Ebay. In this case they were 12v. I didn’t want to purchase any more fans so I opted for a buck converter to step down the 24v to 12v. I connected and adjusted to voltage to about 13v. I used this parts cooler. In my second part I will print out this fan on Thingiverse provided by HE3D and try a radial fan.

First Couple Prints

This turned out really good. I have a couple holes in the mouth but that is a slicing problem. I try to save time so I use very little infill and only 3 top layers.

This one turned out very well as well. It took me several times to print. There was supports already in the STL that were generated by Meshmixer but were thin. After I scaled up the print it worked the first time.

First thoughts

I really wish the printers that I have been reviewing came with good build documentation with the printer and I didn’t have to search for it. This is the biggest downfall of these kit printers. Parts cooling is the next biggest item I don’t know why that is not standard. I was able to overcome the build with the help of the FB group and the HE3D rep was very helpful. One thing that I have to look into fixing is dimensional accuracy. I found parts were off more than I am accustomed to and I believe a calibration issue and will look into this in the next part. They were off over 1 mm. I will also try to find a 12” mirror to print on. I would like to thank Gearbest for sending a review unit. If you are interested in purchasing you can find a link here. [Update 13/12/2017: The following injected molded effector and fans are now included with all printers]

Continue reading HE3D K280 Delta 3D Printer Review – Part 2: Upgrades, Calibration, and More 3D Prints

Karl is a technology enthusiast that contributes reviews of TV boxes, 3D printers, and other gadgets for makers.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

“Build Volume – 280×600”, 200×600 cm, in., mm, angstroms? What? “I followed the k200 youtube videos for the majority of the build”, may we trouble you for a link? When you post pictures of 3D prints either tell us the size of the object or include a ruler in the picture. A picture of a 3D printed object without knowing how big the object is, is next to useless.

Hi, in the second print you can estimate de “Hulk””s size comparing with the printer base’s size.

Little update. After posting article in Facebook group the HE3D rep notified me that they have updated the kit with an injected molded effector and cooling system. they will be shipping it to me. I will hold off on second part until I receive this.

@Karl Johnson

Hmm. I would love to have an injection molded effector and a part cooling system for my K280.

I dig the bed mounts. I think I could adapt that easily to my K280 (which does not use the stock bed attachment method or springs currently). Having to disassemble and re-level in order to access the electronics in the printer base is a HUGE gripe of mine.

Thanks for posting! (Came here from the HE3D FB group.)

Added links to Youtube videos, Facebook group, and added unit for build size (mm).

Not sure if you still check comments. Could I trouble you for the pictures you took of the assembly guide? I only got a corner of one with mine.

Hi karl

(I’m sorry for my English)

I want to ask you if your printer today, a year later, prints like the first day, what are your problems? Any recommendation?

In all the posts I saw, they don’t mention the “injection molded effector and fan” that you say. Do you know if this is so?

Thank you!

Karl, I’m going through the Marlin upgrade process but my board Makerbaase MKS Gen L doesn’t appear in the board list in the Arduino compiler. What board does your printer have?

Found the chipset info. All set for now.

I have had my K280 for about a month. I had similar problems with calibration after I finished assembling the kit. I contacted HE3D and they responded to me. I spent three of my evening which were three of their morning on Skype with them in Beijing China. They were very nice and helpful and did get me a firmware version that worked.

I have one sort of strange problem that one of you all may be able to help me with.

This is the first delta I have had and it is printing well except for one thing anything with text on it come out backwards like a mirror image. Is this firmware or did I do something wrong in the assemble?

Do you know how I fix this?

I suspect your steppers are reversed. Just remember if you swap x and y steppers to also swap x and y endstops the same. You will need to calibrate again after.

Hi Karl; Just assembled the K280 and tested all the movement (homing ) , the bed , extrude heater, fan all work., but every time I try to do auto leveling, the extrude head will partially go off the bed, try very thing I can think of, but just will not auto level the bed. Any help you can point me to? I believe the firmware(marlin 1.1) info. is not correct. Can you share your firmware? Thanks.

Thanks. Yes that is what I suspected and I will try changing them. Also thanks for the reminder about the end stops I have already run into having them wrong once when I first assembled the printer. Was there documentation telling us which was the X and Y? If so I missed it.

When I tried to reply to your comment it tell me Some field is invalided

sorry for the re post, went to the wrong post.

Hi Karl; Just assembled the K280 and tested all the movement (homing ) , the bed , extrude heater, fan all work., but every time I try to do auto leveling, the extrude head will partially go off the bed, try very thing I can think of, but just will not auto level the bed. Any help you can point me to? I believe the firmware(marlin 1.1) info. is not correct. Can you share your firmware? Thanks.

I hope you are still around to anwser this.. but I saw you posted on some live chats on youtube So I setup my K280 printer but following everything the firmware that came with it the Z max endstops which I assume would be the ones at the top it would cause the stepper to grind on the stops they never stopped the motor at all during homing.

It was so bad the little sensor they gave me never stopped if I triggered it I’ve been not too happy with all this.. I even flashed repetier on it and at least it hits the endstops on the top tower.. but the same thing with the nozzle sensor it refuses to stop it even when it’s being triggered. Not sure what else to do.

its total garbage not a very good printer at all

this printer is a piece of shit my frankensbox prints better than this even at the shittiest setting worst purchase ever and barely any manual for it to be found the wiring diagram is vacant ..

Hi Karl

I got a HE3D delta – got it going with Repetier but as you rightly say

The z-hight calibration is good

The x/y axis are totally out. Had anyone got a workaround in the meantime?

iE moving X/Y 30mm it only moves 22mm🤦♂️😩