When you design a circuit board, you first draw the schematics, then the PCB layout, and when you are happy with the result, output Gerber files, and send them to a company who will make a board for you. The last step usually takes a few days, and when you get it back the board may not work as expected, and you have to modify the PCB layout again, and request new boards, further delaying your project. Some students of NYU Polytechnic School of Engineering realized this issue, when only one out of eight teams managed to complete a EEG project on time mainly due to production delays as manufacturers took about 10 days to make and ship back the board. So some of them came together with one of their professor created BotFactory company and came up with Squink, a personal electronic factory, powered by the BeagleBone Black, that can deliver fully assembled boards from Gerber files in a few minutes.

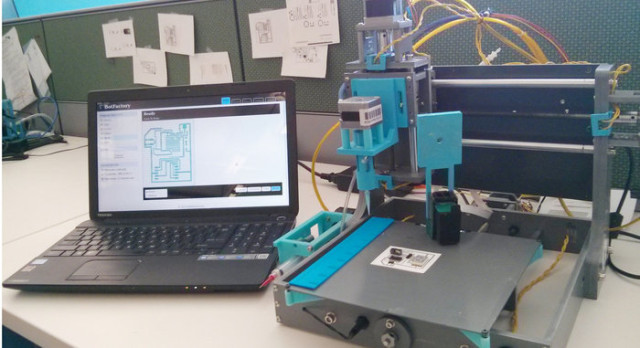

Botfactory feels like the offspring of a 3D printer and a pick and place machine. Once your Gerber files are ready (JPEG, PNG, and BMP image files can also be used), you need to select a rigid or flexible substrate (FP4, Glass, paper…), and access BotFactory web interface to product your board in three steps:

Botfactory feels like the offspring of a 3D printer and a pick and place machine. Once your Gerber files are ready (JPEG, PNG, and BMP image files can also be used), you need to select a rigid or flexible substrate (FP4, Glass, paper…), and access BotFactory web interface to product your board in three steps:

- Print – Conductive ink is applied to the substrate, creating what the developers call “silverboard”

- Glue – Conductive glue dots are applied where components will be placed

- Assemble – Components are picked from a tray and correctly placed on the Glue dots.

There’s also an optional 4th step to heart-cure the circuit on a heatbed for several minutes.

This looks pretty good, unfortunately, it can only be used for single layer PCBs. However, according to their FAQ, multiple layers printing may be supported in a future version:

Will you guys be able to make multi-layer PCB assemblies? How would you go about precisely aligning and gluing together different layers?

*Whisper* This is totally confidential but we are thinking of using insulating ink as a physical separation to make multiple layers. There are positive results so far but it is still a work in progress.There would be no need to align-glue different layers. It would “3D print” a circuit.

Although it will not be available for this version by the time we ship the machines, we are hoping to sell it as an add-on later on.

BotFactory is now trying to raise $100,000 via a KickStarter campaign. Perks for Squink start at $1,999 for the version that only prints (no pick and place), and the full version costs $2,999 if you can wait for the second batch in April 2015, or $3,499 for February 2015 delivery. Free shipping to the US, and $150 to the rest of the world. You can find more on BotFactory website.

Via BeagleBoard.org

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress