Twotrees has sent us a TTC6050 CNC router for review, along with a vacuum cleaner Monster (M1) kit and an 800W spindle upgrade with a speed of 30,000 RPM. The machine is designed for carving and milling various materials such as wood, plastic, and metal. It features a working area of 600 x 500 x 100 mm and comes equipped with a 500W spindle by default, upgradable to an 800W spindle. It’s capable of handling larger workpieces, works faster, and supports a broader variety of materials than the TwoTrees TTC 450 CNC router we reviewed in 2023 with a 500W spindle.

In this review, we will start by listing the specifications and going through an unboxing, before assembling the TTC6050 CNC router and the vacuum cleaner Monster (M1) Kit, and installing the Candle CNC software to conduct milling tests on thick MDF wood. After that, we’ll install the 800W high-speed spindle to the router and cut acrylic sheets, basswood, and carbon fiber with it.

TwoTrees TTC6050 CNC Router specifications and features overview

The TwoTrees TTC6050 CNC is a 3-axis milling and engraving machine designed to support both DIY projects and professional work. It can be upgraded with a laser module (not tested here) or a more powerful spindle, making it versatile for a wide range of applications, including manufacturing, artistic projects, and educational purposes in technology and engineering.

Key features and specifications:

- Spindle – A 500-watt spindle motor with a maximum speed of 12,000 RPM, suitable for high-precision milling and engraving tasks.

- Working Area – 600 x 500 x 100 mm

- Supported Materials – Plywood, MDF, hardwood, acrylic, carbon fiber, aluminum, copper, stainless steel

- Dust protection system prevents dust and debris from entering the drive system, extending the machine’s lifespan.

- Structure – Made of aluminum, equipped with ball screws and linear guide rails on the XYZ axes

- Safety – Infrared sensors to detect obstacles, spindle stop button for safe tool changes, emergency stop

- Expansion – 20W laser module, rotary axis, and an 800W spindle

- Dimensions – 811 x 769 x 530 mm

- Weight – 35.9 kg

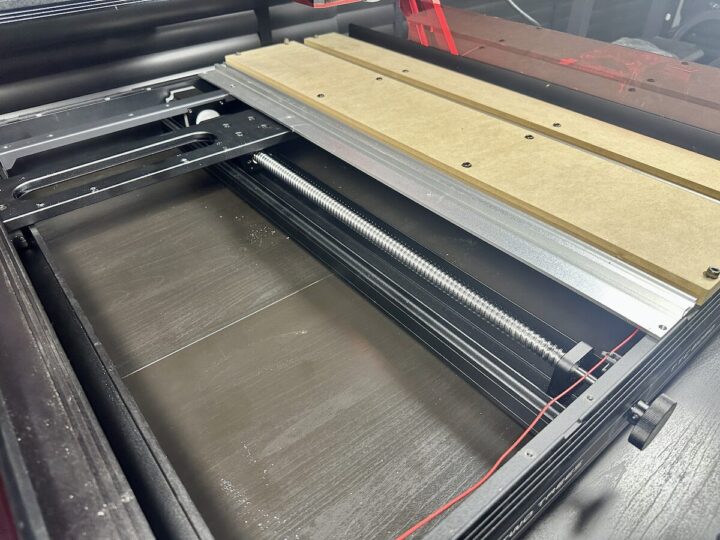

The Y-axis drive system utilizes a large ball screw to control the movement of the workpiece platform. Using a ball screw instead of a belt system enhances movement precision. Additionally, the machine features a replaceable MDF baseboard, which supports the workpiece during milling or engraving. When this MDF board becomes damaged from frequent use, users can replace it without having to disassemble the entire machine.

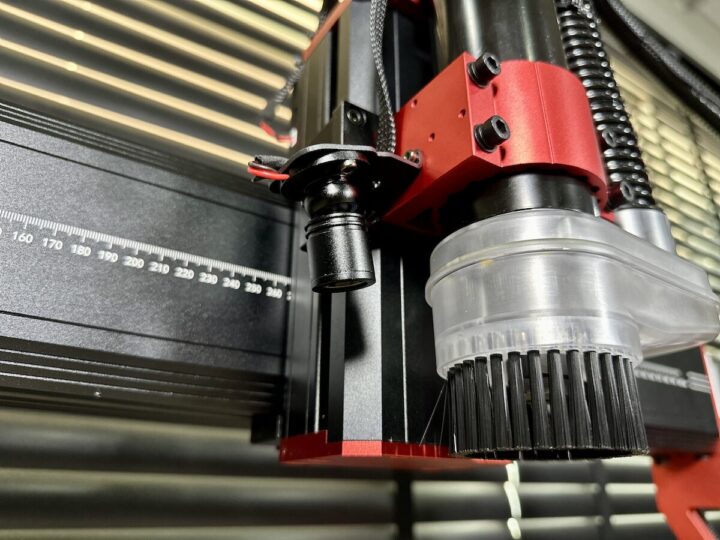

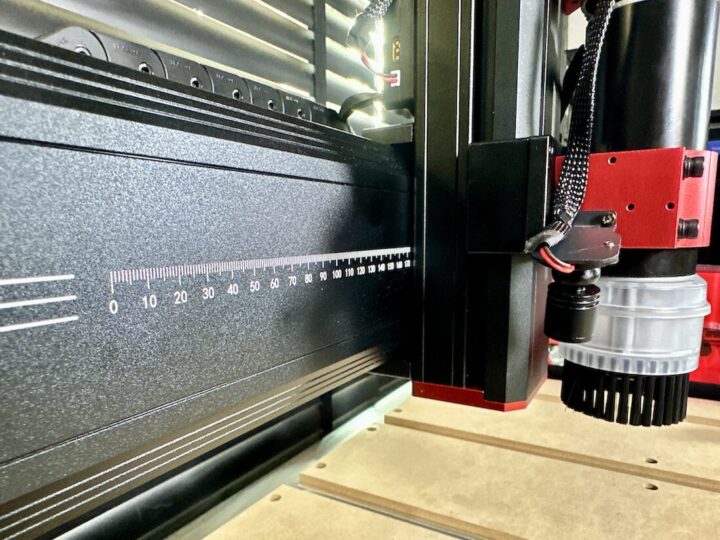

The scale marking on the X-axis structure of the TwoTrees TTC6050 CNC router allows for more precise measurement and positioning of the cutting head. This scale is labeled in millimeters right on the aluminum frame for improved durability. It also facilitates the setup of the workpiece’s origin and repeated positioning for mass production tasks.

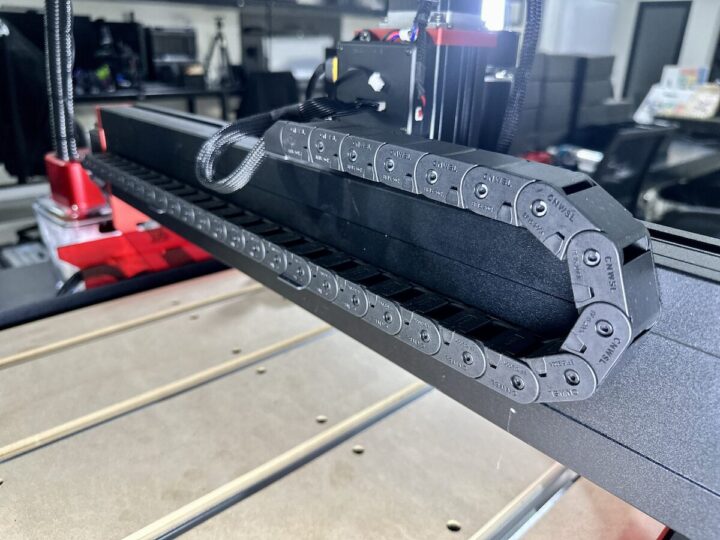

The cable drag chain installed on the TwoTrees TTC6050 CNC machine plays a crucial role in organizing and protecting the power and signal cables that connect the cutting head to the control unit. This prevents tangling or damage due to the movement of the various axes during operation.

The infrared sensors installed on the corners of the TwoTrees TTC6050 machine are part of its safety system. Their primary functions are to detect objects or obstacles that may enter the working area. If an obstruction, such as a user’s hand or another object, crosses into the sensor’s detection range, the machine immediately halts to prevent potential accidents.

The work holding plate installed on the worktable of the TwoTrees TTC6050 CNC machine is used to secure the workpiece in place during milling or engraving. The design incorporates T-slot rails along with threaded screws and hand-tightened nuts, allowing for quick and convenient installation or removal of the clamps. This setup is suitable for workpieces of various sizes and shapes, particularly for DIY projects or prototyping that require frequent material changes. The set includes a total of four clamps.

The TTC6050 has a Y-Axis adjustment knob located at the front of the machine. It allows users to precisely adjust the cutting head’s position before running the program, for instance, to set the workpiece’s origin, verify the workpiece’s position, or calibrate the tools. The knob offers greater convenience and finer precision compared to using a mouse or on-screen buttons, especially for tasks requiring high accuracy prior to milling.

As you might have expectd, there’s also a Z-axis adjustment knob…

… and an X-axis adjustment knob for the same reasons.

The kit also ships with personal protective equipment (PPE) essential for operating the CNC machine safely: safety goggles and ear protection.

The Control Box of the CNC machine includes the following key buttons and functions:

- Emergency stop button to immediately halt the machine’s operation in emergency situations, such as malfunctions or potential hazards to the user. It completely shuts down the machine for maximum safety.

- Spindle safety button to turn the spindle circuit on or off, allowing safe tool changes by preventing unintended spindle rotation.

- Speed control knob to adjusts the spindle speed from MIN to MAX, enabling users to control the rotation speed of the cutting head to suit the material being worked on

The rear panel of the control box comes with various ports and features:

- Power Switch (red)

- Power Input port with a built-in fuse to protect the system from power surges.

- Cooling fan opening to aid in dissipating the heat from the power supply and internal control board.

- USB Type-B and serial ports to connect to a computer for control

- A data interface port to control the motors, switches, and sensors on each axis of the machine.

- A WiFi antenna

The USB port at the top is used to connect the CNC router to a computer, enabling the transfer of control commands or G-code to the machine. The data interface port right under is used to connect a ribbon cable to transmit control data to the motors, switches, and sensors on each axis of the machine.

The touchscreen display of the TwoTrees TTC6050 CNC router serves as a user interface to operate the machine without a computer. It features a user-friendly menu system with clearly labeled icons, making it suitable for both beginners and experienced users. The main functions visible on the screen include:

- Axis movement controls – Buttons to control the X, Y, and Z axes, along with options to set the origin points (XY origin / Z origin).

- Movement resolution selection – Allows users to choose the precision of movement (e.g., 1mm increments).

- Icons for “Speed,” “Tools,” “File,” and “Settings” to control spindle speed, tool configuration, selection of G-code files, and adjustment of various system settings.

- Cutting head coordinates are shown at the top corner of the screen

The main menu offers the following:

- Top menu – Language, WiFi, Help, Contacts (contact information for support services)

- Sub-menu

- About – Displays machine details such as model, dimensions, and firmware version.

- Beep (OFF/ON) – Toggles the machine’s alert sound on or off.

- Engrave (CNC Mode) – Switch operating modes, e.g., from laser to CNC or vice versa.

- Right-side menu (Quick Access):

- Tools – Access the tools menu for tasks like calibration or spindle setup.

- File – Browse saved or uploaded G-code files.

- Back arrow to return to the previous screen.

Eight languages are selectable: (simplified Chinese), English, Deutsch, (Russian), (Japanese), Français, Português, and Español.

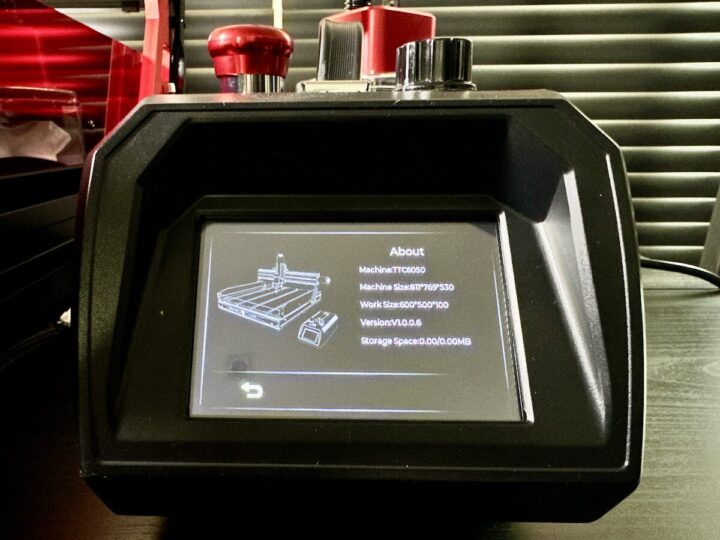

The About menu gives us some of the key features of the machine, firmware version, and storage space:

- Machine: TTC6050

- Machine Size: 811 × 769 × 530 mm

- Work Size: 600 × 500 × 100 mm

- Version: V1.0.0.6 – Firmware version

- Storage Space: 0.00/0.00 MB – Zeo since we didn’t install a microSD card in the machine.

We can scan the WiFi access points with the WiFi option.

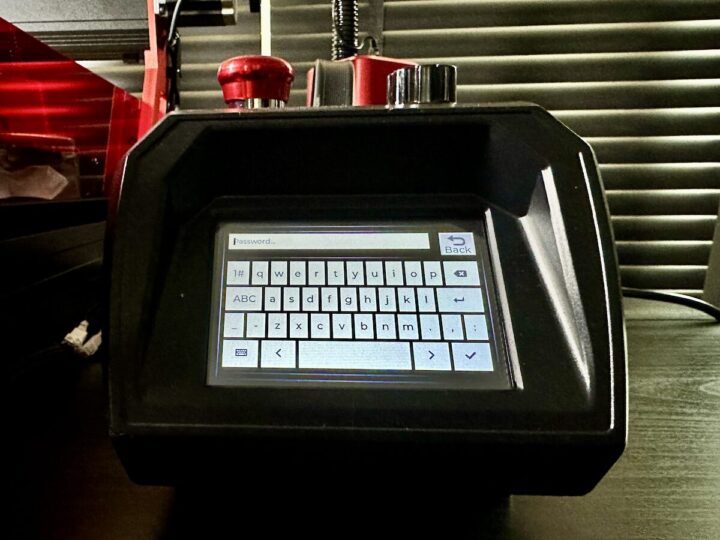

Once you’ve selected the ESSID you want to connect to, you’ll be presented with a software keyboard to input the WiFi password.

The 500W spindle that ships with the TwoTrees TTC6050 CNC router is a powerful cutting head suitable for a variety of tasks, including milling wood, plastic, acrylic, and light metals such as aluminum or copper. This spindle achieves a maximum speed of 12,000 RPM, delivering smooth, precise cuts and minimizing material chipping when paired with the appropriate milling bit. It also features a built-in fan cooling system for continuous operation without overheating.

Twotrees CNC Vacuum Cleaner Monster (M1) Kit overview and installation

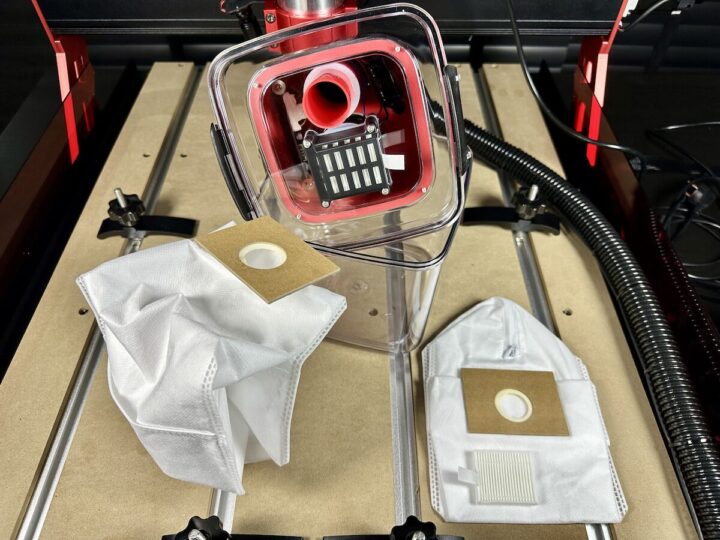

The Twotrees CNC Vacuum Cleaner Monster (M1) Kit is an accessory designed to enhance the performance of CNC machines, particularly the TTC450 and TTC450 Pro models. It features a brushless motor with a maximum speed of 50,000 RPM, delivering powerful and durable suction for long-term use.

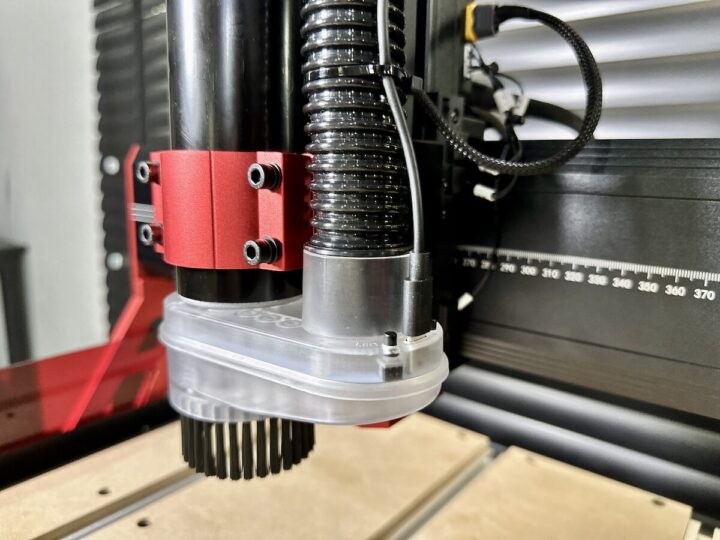

The dust collection nozzle of the Vacuum Cleaner Monster (M1) attaches directly to the cutting head of the CNC machine. Its transparent design allows users to monitor the spindle’s operation at all times. The nozzle is equipped with silicone brushes around the edge that sweep dust into the suction port while preventing debris from scattering. The suction hose is securely fastened to the cutting head so that it doesn’t loosen or whip around during machine movement. The setup significantly reduces dust in the workspace, as we’ll demonstrate below.

Key Features and specifications:

- Automatic start/stop function in sync with the CNC machine’s operation

- An LED light is integrated into the suction head for clear visibility of the work area even in low-light conditions.

- 2.8-liter dust bag with zipper for easy dust removal and cleaning.

- Transparent body to allow the user to monitor the dust level inside.

- Long flat nozzle for efficient cleaning of narrow and hard-to-reach areas.

- Operating Modes – Adjustable with 2 levels

- Continuous Operation Time – Up to 48 hours

- Power Supply – 24V 3A adapter; machine rated 70W

- Dimensions

- Unit – 170 x 170 x 240 mm

- Suction hose – 1.2 m long (32 mm diameter)

- Weight – 1.4 kg

The magnetic dust shoe of the CNC vacuum kit Monster (M1) can be removed from the cutting head of the CNC machine to provide easy access to the end mill mounted on the 500W spindle. This allows the user to swap out end mills or perform cleaning tasks without needing to disassemble the suction hose or other components entirely. The bottom edge of the dust shoe retains a rubber brush border, which prevents debris from scattering and enhances the efficiency of dust suction by directing airflow effectively.

The end mill protrudes through the central opening of the dust shoe. This design allows an effective collection of debris and dust generated during milling without impacting the machine operation. The lower edge of the dust shoe is equipped with rubber or silicone bristles acting as a barrier to prevent material fragments from scattering and sweeping dust toward the suction port.

A USB Type-C cable connects to the dust shoe of the CNC Vacuum Cleaner Monster (M1) kit to power the LED. There’s also a switch located on the side next to the USB Type-C port to turn on/off the LED.

The top of the CNC vacuum cleaner Monster (M1) features an on/off switch, USB Type-A port (for the LED), a power input port, and “Max” and “Min” LEDs to report the current operating mode of the vacuum. There’s also an air hose to collect the debris while operating.

The power adapter for the machine (Model BZ065-240300-E2) takes 100-240V~ 50/60Hz input and outputs up to 24.0V/3A (72.0W).

TwoTrees CNC Vacuum Cleaner Monster (M1) ships with 2.8L dust collection bags made of fine fiber fabric and a fine dust filter located inside the machine (right under suction port in the photo below) to filter micron-level dust before air exits the unit. This extends the motor’s lifespan and prevents dust from dispersing back into the environment.

An additional spotlight LED is mounted near the cutting head of the CNC machine, and positioned right above the Monster M1 dust shoe. It emits a focused beam targeting the end mill for improved precision and clarity in the work area.

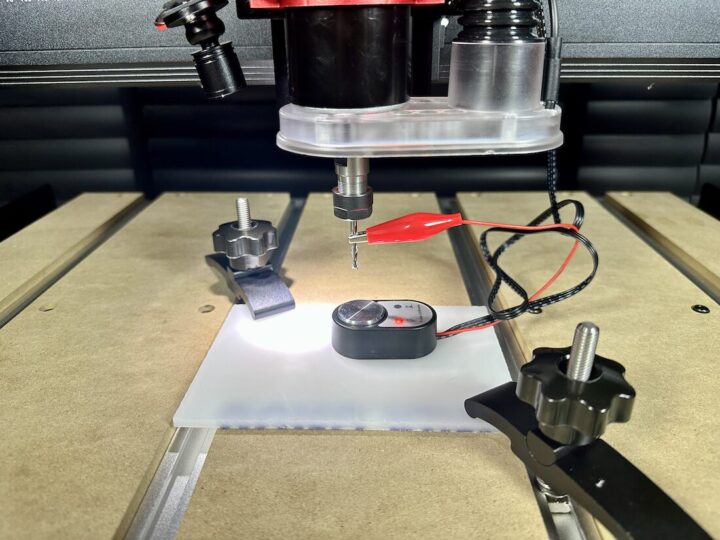

The Z-Probe, also called the Z-axis auto tool setter, is an accessory used with the TwoTrees TTC6050 CNC router to automatically and precisely set the Z-axis origin.

Here’s how it works:

- The machine gradually lowers the Z-axis head.

- When the end mill comes into contact with he probe plate, it closes the circuit, sending a signal to the control box.

- The system records the Z-axis position and automatically raises the cutting head.

-

The user can use this value as a reference for milling at various depths with greater accuracy.

Advantages of using a Z-Probe:

- Reduces manual errors

- Saves time

- Suitable for high-precision tasks such as engraving or milling multi-layered material

Candle CNC software

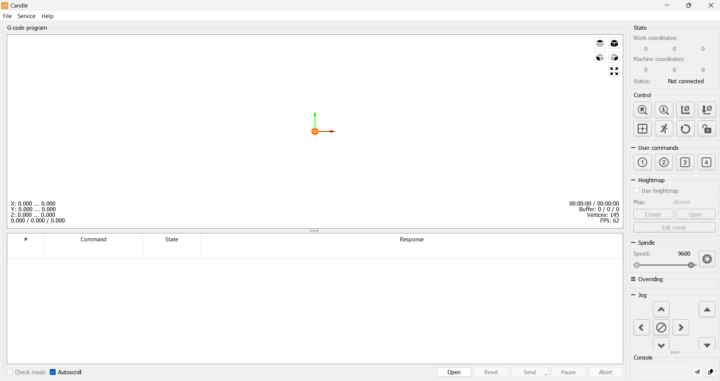

Candle is a popular CNC control software that directly interfaces with the GRBL firmware. It can be installed from the flash drive included with the machine or downloaded from GitHub.

The Candle Interface has four main zones:

- Top menu with File, Service, Help. Mostly used to load .nc or .gcode files

- G-code program

- The central area displays a simulation of the X, Y, and Z axis positions, along with the tool path that the cutting head will follow based on the G-code commands.

- The bottom-left corner shows the current X, Y, and Z coordinates of the cutting head.

- Coordinates are displayed in both Work Coordinate and Machine Coordinate systems.

- Right-side panel

- Status to indicate whether the machine is connected to the computer (via USB)

- Control section with various buttons for loading files, resetting, or pausing operations.

- User Commands Buttons (1–4) – Customizable shortcuts for G-code commands, such as setting the origin or moving to zero.

- Spindle Speed Control: Adjusts the spindle’s rotation speed.

- Jog Control Buttons: Manual control for moving the XYZ axes.

- Console Area: Located at the bottom, allows direct G-code input.

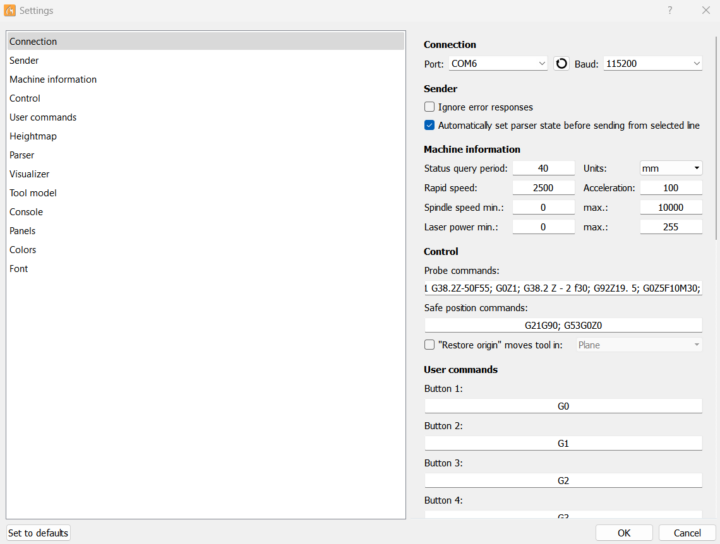

The screenshot below shows the Settings window of the Candle software with some of the most useful options being:

- Connection – Port (e.g., COM6) and baudrate (set to 115200, the standard rate for GRBL).

- Sender – Configures the software to automatically send commands along with parser state information, enabling GRBL to recognize the current mode, such as G90 (absolute) or G91 (relative).

- Machine Information

- Status query period – The interval for requesting status updates from the machine (default is 40ms).

- Rapid speed – The speed for rapid movements (2500 mm/min).

- Acceleration – Set to 100 mm/s².

- Spindle speed – 0 to 10,000 RPM.

- Laser power – From 0 to 255.

- Control

- Probe commands – Commands for automatic Z-axis leveling using a probe, e.g., G38.2 Z-50 F55; G0Z1; G38.2 Z-2 F30; G92Z1.9; G0Z5F100; M30;.

- Safe position – Defines a return to a safe position, e.g., G21G90; G53G0Z0;.

- User commands – Buttons 1–4: Customizable shortcuts for frequently used G-code, such as G0: Rapid movement, G1: Controlled movement with feed rate, G2/G3: Arc movements.

Milling Test of the TCC6050 CNC router

A milling test was conducted without activating the dust collection system, resulting in a noticeable spread of material debris across the base and surrounding area. This highlights the drawbacks of not utilizing the included dust extraction system, such as the CNC Vacuum Cleaner Monster (M1).

Problems encountered without the dust collection system:

- Fine particles and dust were scattered widely across the work area.

- Potential clogging as dust could accumulate in the linear rails or ball screws, potentially causing movement interruptions.

- Increased cleanup effort after operation.

- Health risks due to inhaling fine dust, especially from materials like MDF or plastics.

- Reduced visibility since the dust obscures the cutting area, making it harder to monitor the work or detect anomalies.

So going forward, we enabled the CNC Vacuum Cleaner Monster (M1) for all other tests.

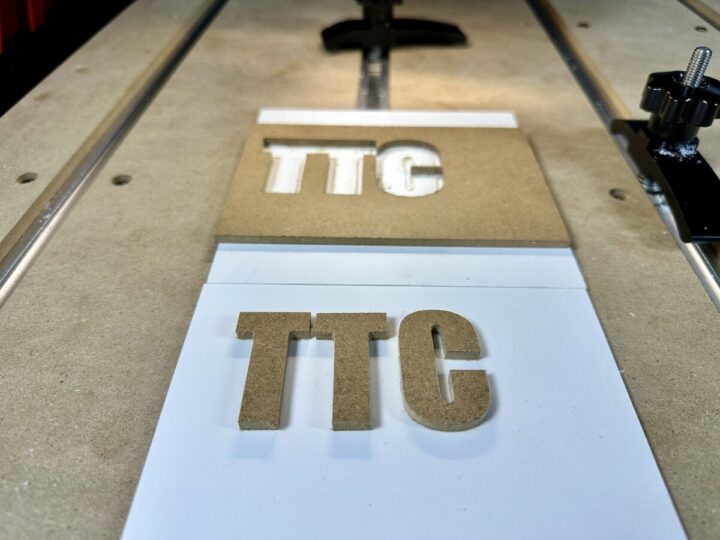

Then we cut MDF (Medium-Density Fibreboard) wood with the TwoTrees TTC6050 CNC machine using a 500W spindle to drill and cut the letters “TTC” from the wood sheet. The result looks good and the cut was done at a speed of 1000mm/s.

Cutting Details:

- Material: thick MDF wood

- Type of work: cut-through

- Result: obtained both positive piece (the cut-out letters) and negative piece (the pierced sheet)

- Edge quality: smooth edges, no burns or chipping

- Tool: pointed or straight end mill suitable for wood cutting

Highlights of the result:

- High precision in size and shape

- Suitable for decorative work, letter signs, or DIY projects

- Supports both cutting and deep engraving

Twotrees 800W 30000RPM Wood Router Machine

The CNC machine can be upgraded with an 800W spindle reaching a maximum speed of 30,000 RPM, an improvement over the standard 500W/12,000RPM model. The company calls it the “800W 30000RPM Wood Router Machine”

Upgrade Details:

- The blue-gray spindle is an 800W router head, providing increased power for heavy wood milling tasks.

- It fits perfectly onto the TwoTrees TTC6050 using the original mounting plate and follows the same wiring setup.

- Built-in cooling fan on the spindle head to dissipate heat during continuous operation.

- Additional power cable with a connector for a separate power supply from the main control unit.

Advantages of the Upgrade:

- Higher RPM allows for faster and smoother milling.

- Supports thicker and harder materials, such as thick MDF, acrylic, or even thin aluminum.

- Expands the variety of projects that can be produced.

Key features/specifications:

- High-power 800W motor to handle a wider range of wood engraving and trimming tasks.

- High 30,000 RPM to ensure efficient operation and smooth results.

- User-friendly design enables easy handling and precise control during milling.

This upgraded 800W spindle enhances the original CNC machine spindle, featuring the following key components:

- On/Off switch

- Located on the side of the motor.

- Convenient for directly controlling the spindle’s operation.

- Should be manually turned on/off before and after use for safety.

- Speed dial

- Positioned on top of the router head.

- Adjustable across 6 levels

- Allows speed adjustment from approximately 10,000 to 30,000 RPM.

- Speed should be selected based on the type of cutting bit and material:

- Low speed: For hard materials like aluminum.

- High speed: For softer materials like wood or plastic.

- Top ventilation slots

- Facilitates heat dissipation during continuous operation.

- An internal fan draws air through these slots to prevent the motor from overheating.

- Important notes:

- Since this spindle’s speed is controlled directly on the device, it cannot be adjusted via software. Speed must always be set manually before milling begins.

- It cannot be installed with the CNC Vacuum Cleaner Monster M1 Kit.

The control box of the TTC420 800W Wood Trimmer Router has the following specifications:

- Model: TTC420 Wood Trimmer Router

- Rated Power: 800W ± 10%

- Rated Voltage/Frequency:

- 110V / 60Hz

- 220V / 50Hz

- No-load Speed: 10,000 – 30,000 RPM

- Speed Gear: 6-speed regulation

- Chuck Type: ER11

- Motor Type: Universal Motor

- Control Mode: Manual / Signal Control

- Control Box Weight – 0.35 kg

- Router Weight – 1.415 ± 0.1 kg

Connecting the TTC420 800W spindle control box involves attaching the signal cable using a threaded locking connector. This setup links the control signals from the CNC controller to the router. Additionally, a red rocker power switch is used to turn the power on and off.

Testing the TwoTrees TTC6050 CNC Router with the 800W spindle

We’ll start our test of the 800W spindle by cutting acrylic with the CNC machine. This will demonstrate the machine’s ability to cut hard plastic materials at a speed of 1000mm/s, with 2 passes.

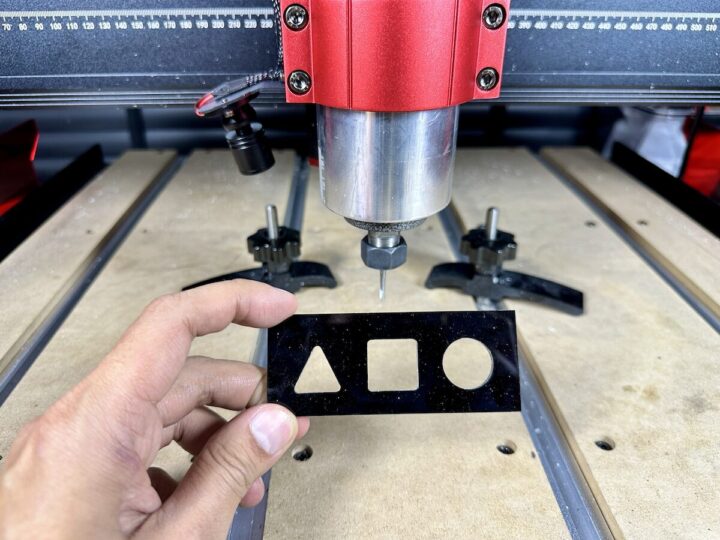

Next up will be an engraving test on black acrylic at a speed of 1000mm/s and with only one pass.

Details of the test:

- Engraved Text “CNX” that’s sharp, clean, and deep

- Small engraving bits suitable for detailed work were used

- The acrylic workpiece was secured with two clamps on the MDF base

Highlights observed from the workpiece:

- The spindle speed control ensures precise engraving.

- The engraved surface is clean with no debris accumulation, indicating sharp cutting performance.

- This type of engraving can be used to create logos, nameplates, or decorative pieces.

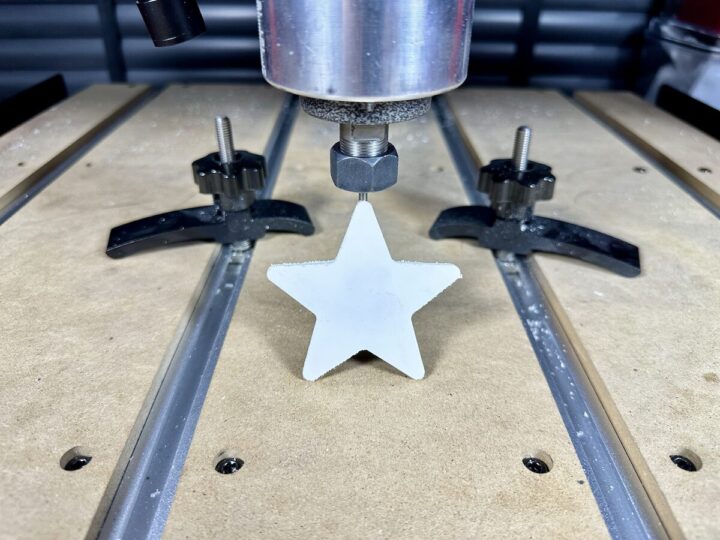

We then cutplaswood with the CNC Machine using a five-pointed star model with a speed of 2000mm/s in a single pass

Details:

- Material: Plaswood (white laminated plywood), moderately dense, suitable for milling and cutting.

- Shape: Five-pointed star with sharp, smooth edges, no chipping.

- Workpiece securing: Firmly clamped on both sides.

- Tool: small-sized cutting bit with appropriate speed.

Highlights of the work:

- Ideal for creating models, decorative items, or DIY projects.

- The workpiece was cut through the sheet cleanly.

- The CNC machine performed responsively, producing results true to the design.

In our final test, we cut a carbon fiber sheet using the same module with a speed of 500mm/s and four passes.

Details:

- Material: Carbon fiber – strong, lightweight, with a distinctive woven carbon pattern.

- Shape: Five-pointed star as above

- Workpiece securing: Clamped firmly on both sides to prevent movement during milling.

- Tool: high-speed small bit, suitable for hard materials.

Recommendations:

- Cutting carbon should involve a dust collection system or wearing a particulate mask, as carbon dust may irritate the respiratory system.

- Use high RPM but avoid deep pressure per pass to minimize edge tearing.

Video review of the TwoTrees TTC6050 CNC Router

The video below includes an unboxing, assembly instructions, and all tests we have done above.

Conclusion

The TwoTrees TTC6050 CNC router machine is a versatile milling tool capable of cutting, engraving, and drilling a wide range of materials, including wood, acrylic, and even carbon fiber. It features a sturdy structure, a worktable that supports large projects (600x500x100mm), and an easy-to-use touchscreen control system with spindle speed control, an emergency stop button, and USB connectivity.

The machine works well with the Candle software, the provided Z-probe makes configuration easy, and accessories such as goggles and ear protection enable users to operate the machine safety whether they are beginners or professional users.

The TwoTrees CNC vacuum cleaner Monster (M1) Kit significantly enhances CNC operation. It attaches to the 500W spindle with brushes and a suction hose that instantly removes debris from the cutting area. It also features a USB-C-controlled LED light bright enough for dark workspaces, powered by a 24V adapter. The internal filtration system, with a dust bag and filter, keeps the work area clean and safe.

The TwoTrees 800W 30000RPM Wood Router Machine allows an easy upgrade with an 800W spindle offering higher speed and torque, suitable for more demanding tasks like cutting thick materials, hard acrylic, or carbon fiber. It includes a separate control box with an on/off switch and signal cables for precise operation control. Two downsides are that the speed can not be controlled by software and must be set with the know on the spindle, and it is not compatible with the vacuum cleaner Monster (M1) kit.

To summarize, the TwoTrees TTC 6050 CNC router is suitable for serious CNC beginners to mid-level professionals seeking an upgradable machine. With a relatively large work area, support for diverse materials, and reliable continuous operation, it’s useful for model-making, signage, part engraving, or professional-quality DIY projects.

We’d like to thank TwoTrees for providing the TwoTrees TTC 6050 CNC machine, the Monster M1 vacuum cleaner kit, and the 800W 30,000 RPM spindle for review. These can be purchased from the company’s online store with the TwoTrees TTC 6050 CNC router going for $1,799, the Monster M1 vacuum cleaner selling for $99, and the 800W spindle adding an extra $79.95. Alternatively, the machine is also listed on Amazon US for the same price.

CNXSoft: This review is a translation – with some edits – of the original article on CNX Software Thailand by Kajornsak Janjam, edited by Suthinee Kerdkeaw.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

> a relatively large work area

I had to giggle a bit after having recently watched this guy building his CNC machine himself: https://www.youtube.com/watch?v=Ag6NPmzNri8&t=39s 🙂