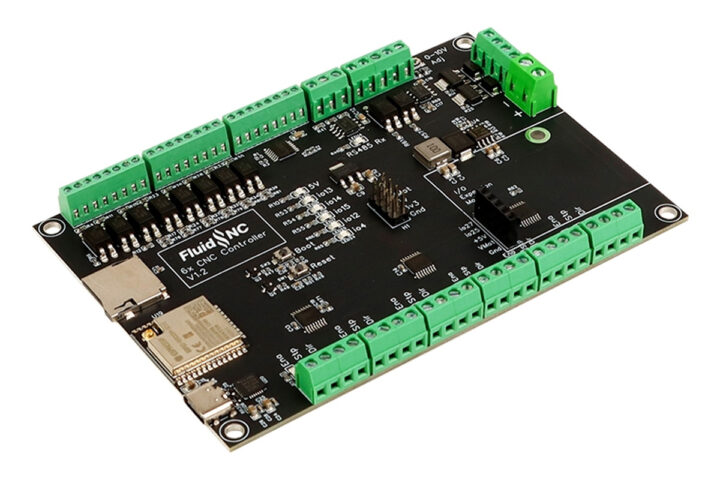

US-based CNC and motion control developer Bart Dring has designed the 6x CNC Controller FluidNC-compatible CNC controller board built around an ESP32 (pre-programmed with FluidNC) module and including 6 external stepper motor drivers with 5V signals. It allows configuration, upgrades, and control via a web browser.

The controller also includes individual step/direction controls and LED indicators for easy setup. It offers eight input ports for limit switches, probes, and controls, along with multiple spindle control options, including RS485 VFD, 0-10V, PWM, relay-based, brushless motor (BESC), and laser PWM with enable signals. Additionally, it has two 3A MOSFETs for relays or solenoids, a MicroSD card slot for local G-code storage, and an expansion socket for GPIO extenders or pendant interfaces.

6x CNC Controller specifications

- Wireless module – Espressif Systems ESP32-WROOM-32E

- ESP32 dual-core microcontroller

- 4MB flash

- 2.4 GHz WiFi and Bluetooth LE connectivity, built-in PCB antenna

- Storage – MicroSD card socket for local G-code file storage

- Connectivity – 2.4GHz Wi-Fi 4

- Motor Channels – 6x stepper motor drivers (5V signals, separate step, direction, and enable signals with LEDs)

- Laser Control – PWM and enable signals for laser control

- Inputs – 8x Isolated switch inputs for limits, probes, and controls

- Outputs – 2x 3A MOSFETs for relays, solenoids, and valves; unused spindle 5V outputs can be repurposed

- USB – USB-C connection for FluidNC configuration and firmware updates

- Expansion:

- Support for NPN proximity/inductive sensors (ground-switching type)

- Expansion module socket for GPIO extenders, Pendant interfaces

- Misc

- External pull-up resistors on all inputs (except GPIO.2 and GPIO.26)

- LEDs for Step, Direction, and Enable signals on each motor output

- Status LEDs for power, spindle, and MOSFET outputs

- Hardware emergency stop (E-stop) input

- Web-based interface for configuring FluidNC

- Power

- 12-30V DC input (VMot) with a minimum 2A requirement

- Central voltage access header:

- 3.3V (100mA max)

- 5V (500mA max)

- VMot (1A per pin max)

- MOSFET terminals provide up to 3A per pin

- No reverse polarity protection (incorrect wiring may damage the controller)

- Dimensions – 125 x 85mm

This FluidNC-compatible CNC controller board is completely open sourced and all the files including the schematic and board files are available for download from EasyEDA. In terms of software, the board is designed to work with the FluidNC firmware, which can be installed and updated via a web-based installer. Configuration files define the specific hardware setup, including motor drivers, switches, and spindle controls. While the controller ships with a basic config file for testing, users typically need to create a custom configuration file tailored to their machine’s setup. More information can be found on the wiki.

We previously wrote about another ESP32-based FluidNC-compatible CNC controller board designed specifically for pen plotters and lasers, also running FluidNC firmware. We also just covered the Tobor (robot spelled in reverse), a modular, open-source robotic arm platform featuring an ESP32-WROOM-32 module preloaded with the FluidNC firmware.

This 6x CNC Controller is available on the Tindie store for $64.00, but you’ll find it for a lower price on Elecrow ($49).

Debashis Das is a technical content writer and embedded engineer with over five years of experience in the industry. With expertise in Embedded C, PCB Design, and SEO optimization, he effectively blends difficult technical topics with clear communication

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress