PCBWay, one of the most popular PCB manufacturers in China, has been offering flexible PCB manufacturing services for years, but the company has recently added new parameters and special processes to its flexible PCB ordering page.

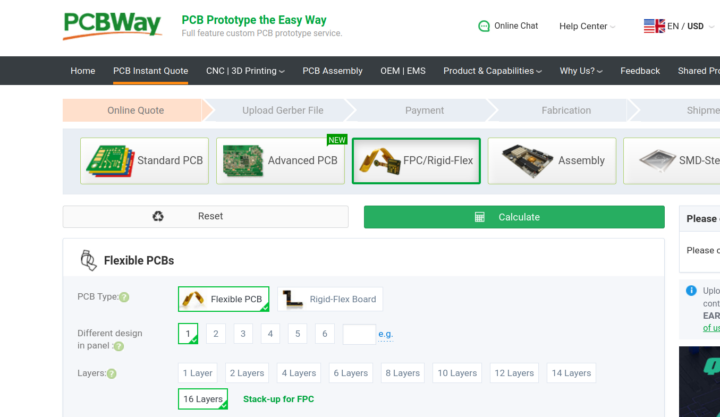

The first change is that customers can now order more complex flexible PCBs with up to 16 layers when using Polyimide Flex base material.

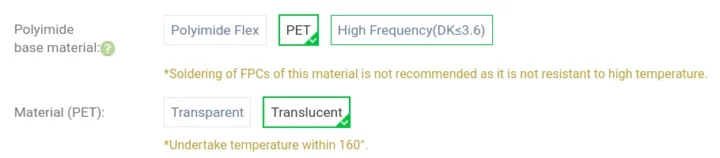

PCBWay also added support for “high-frequency (DK<=3.6)” material with a dielectric constant of under 3.6 at 1 MHz as well as “Transparent” and “Translucent” options for PET material in the Polyimide base material section.

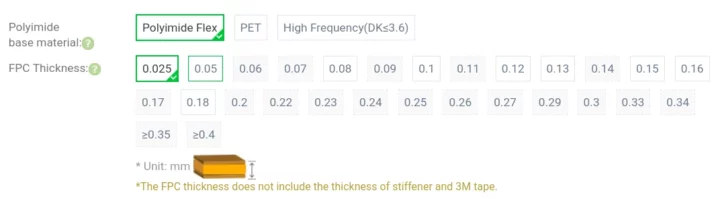

Additional FPC thickness options have also been introduced with 0.025 and 0.05mm for one-layer boards and 0.08mm for two-layer boards enabling ever-thinner designs.

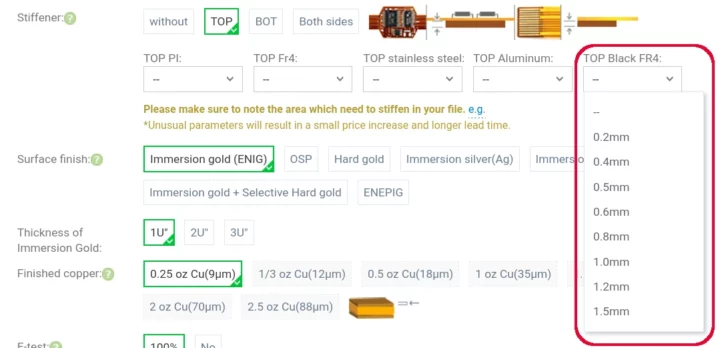

Customers have now more choices when ordering stiffeners – the rigid part of a FlexPCB – with the “TOP Black FR4” and “BOT Black FR4” options with thickness options including 0.2mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, and 1.5mm. PCBWay already supported PI, FR4 (green), stainless, and aluminum stiffeners, so Black FR4 adds to the list.

Finally, a field has been added to the ordering form for conductive double-sided tape with the option to do without or select either HT-A1134 or HDF-600 from a drop-down menu. A conductive double-sided tape is added to the flexible PCB so that it can be attached to other objects and the tape can conduct electricity.

PCBWay has also ramped up its flexible PCB production capacity and can now accept orders for up to 3,000 flexible PCBs. The PCB manufacturer has also added more customization and advanced options with additional “special processes” that include:

- Peelable solder mask – Also known as a blue peelable mask, it is used to protect the required solder pads during assembly and is typically referred to as GTPM and GBPM in design.

- Half-cut/castellated holes

- Edge plating – PCB edge plating refers to the metallization of the sides of a printed circuit board across its height.

- Via filled with copper

- Stiffener between top and bottom edge connector – The stiffener is laminated between the top and bottom edge connectors to rigidize the edge connector area and does not influence the contact on either the top or bottom layers.

- Single-Side Double Access – A double-access flex circuit is a single-sided flex circuit that is manufactured so that the conductive material can be accessed from both sides of the circuit.

If you think you have a flexible PCB design that may benefit from those new options, you can place an order directly on PCBWay with your hardware design files and parameters.

This account is for paid-for, sponsored posts. We do not collect any commission on sales, and content is usually provided by the advertisers themselves, although we sometimes write it for our clients.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress