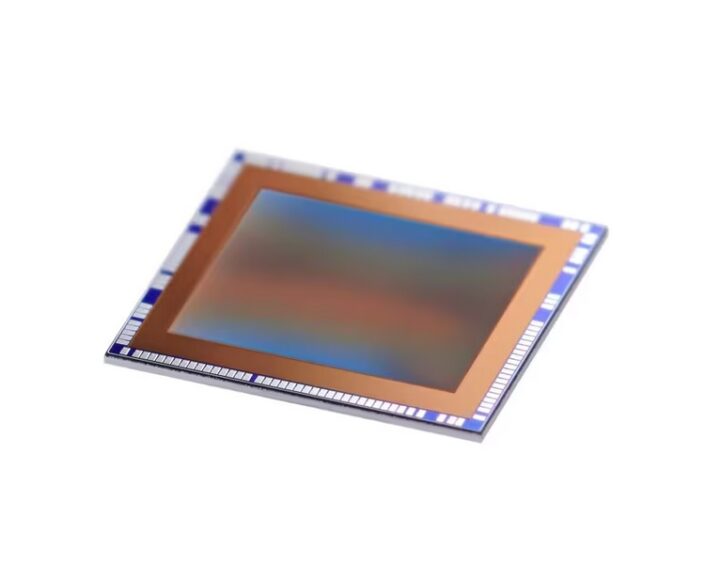

The STMicro VL53L9 sensor is the latest addition to the company’s FlightSense product family. The direct Time-of-Flight (ToF) 3D LIDAR (light detection and ranging) sensor offers a resolution of up to 2,300 zones. The module is described as all-in-one and easy to integrate. It comes in a small, reflowable package that contains all the necessary components for sensing objects and processing images.

The sensor features an array of single photon avalanche diodes (SPADs) for photon detection, a post-processing SoC, and two vertical surface emitting lasers (VCSELs) powered by a dedicated bipolar-CMOS-DMOS (BCD) VCSEL. The VL53L9 is a multi-zone ToF sensor similar to the VL53L7CX and the VL53L8, meaning that it offers multi-zone distance measurements up to 54 x 42 zones with a wide 54° x 42° field-of-view.

Unlike most IR sensors, the VL53L9 sensor uses backside illumination direct ToF technology to ensure absolute distance measurement, regardless of the target color and reflectance. It captures 2D IR images and 3D depth map information at <5cm up to 10m using dual-scan flood illumination, a unique system according to the company. It can then stream the 2D image, depth information, and a confidence map at a 60Hz frame rate (which the company claims is the fastest on the market).

STMicro VL53L9 key features and specifications:

- Wide field of view

- Emitter: 940 nm invisible light vertical cavity surface emitting laser (VCSEL) and integrated analog driver

- 71° diagonal field-of-view (FoV) using metasurface optical elements (MOE) on both transmitter and receiver

- Receiving array of single photon avalanche diodes (SPADs)

- Speed and accuracy

- Resolution: up to 54 x 42 (2,268) separate zones and binning options

- Post-processing SoC can stream a 2D infrared (IR) image with a depth and confidence map

- Range: <5 cm up to 10 m

- Frame rate: 60Hz

- Scan by two vertical-cavity surface-emitting lasers (VCSEL) flood illumination

- Histogram processing and algorithmic compensation

- All-in-one module with integrated SPAD sensor and VCSEL power management integrated circuit (PMIC)

- Power – Dual power supply operation: 1.2V and 3.3V

- Compatible with a wide range of cover glass materials

- Dimensions – 12.8 x 6.1 x 4.6 mm (miniature reflowable package)

- Safety – Class 1 certification for eye-safe operation and additional skin protection in normal use

The company expects the VL53L9 sensor to find applications in:

- Telephoto zoom camera assist.

- Augmented reality/virtual reality (AR/VR) enhancement.

- Laser-assisted autofocus (LAF).

- 3D room mapping and obstacle detection or SLAM (simultaneous localization and mapping) for robotics applications

- Content management (liquid level control, load in trucks, tanks, waste bins)

- Gesture recognition

- Smart buildings and smart lighting (user detection to wake up devices)

- Internet of Things (user and object detection)

In other news, ST has also announced a design win for the earlier-released VD551, a low-power, indirect Time-of-Flight (iToF) sensor. A design win means that a company has ordered 500 or more units of the sensor to integrate into their product. In this case, that company is Lanxin Technology, a Chinese company with a focus on mobile robot deep vision systems. MDDVS, a subsidiary of Lanxin, has selected the VD551 to bring high-accuracy depth-sensing to its 3D camera.

Mass production of the STMicro VL53L9 sensor is scheduled for early 2025 and samples are currently available for select customers. Pricing details and samples can be requested at local ST sales offices. You can find more information in the press release and the VL53L9 product page.

Tomisin is a writer specializing in hardware product reviews, comparisons, and explainers. He is very passionate about small form factor and single-board computers.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress