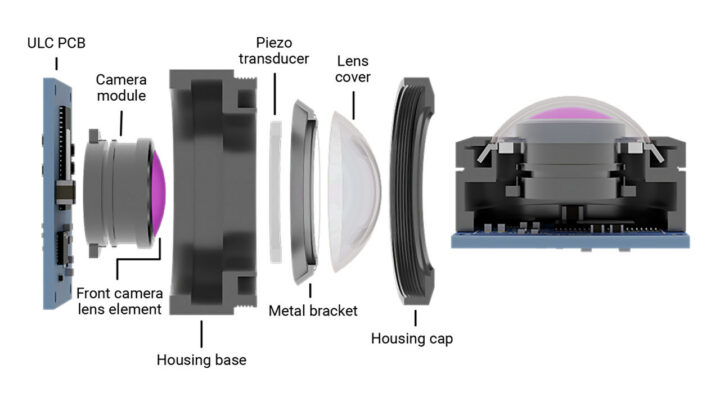

Texas Instruments (TI) has introduced the ULC1001 digital signal processor (DSP) ultrasonic lens cleaning (ULC) technology designed – when combined with DRV2901 piezo transducer driver – for self-cleaning camera systems to quickly detect and remove dirt, ice, and water using microscopic vibrations.

Cameras used in the automotive, industrial, robotics, and smart farming industries may require cleaning from time to time and that usually means manual cleaning leading to potential downtime, higher maintenance cost, and so on. It could also be done through mechanical parts but that adds further complexity to the system, so instead, Texas Instruments ULC1001 and DRV2901 combo enables cameras to rapidly self-clear contaminants using vibrations to eliminate debris.

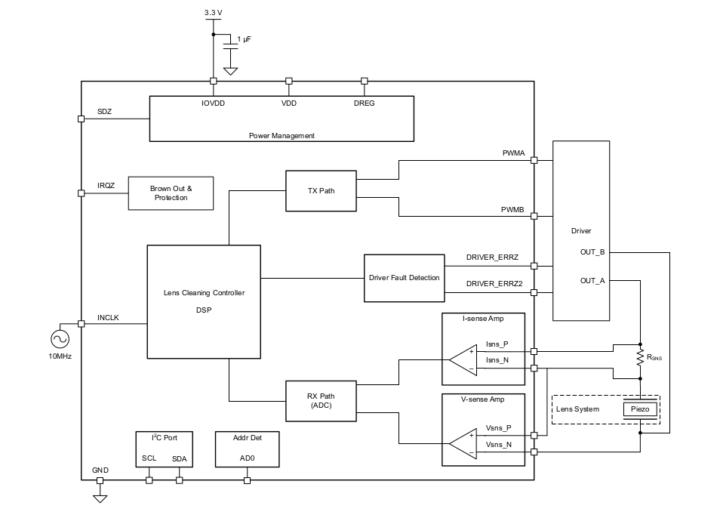

The datasheet describes the ULC1001 as a “Configurable Ultrasonic PWM Modulator With I/V Sense Amplifiers” with the following specifications:

- Integrated Programmable Cleaning Modes

- Water (expelling)

- Deice (melting and expelling)

- Mud (dehydrating and expelling)

- Auto-Cleaning (detecting and expelling)

- Custom Cleaning Modes

- Embedded Algorithms

- Lens System Calibration

- Automatic Material Detection

- Power Regulation

- System Diagnostics

- System Diagnostics

- DRV290x Fault Reporting

- Lens System Fault

- Transducer Temperature Regulation

- Wide Drive Frequency Range

- High-Efficiency Direct Drive (25 kHz – 5 MHz)

- AD Modulation (<50 kHz)

- Host interface – I2C

- Clock Source – External Oscillator (10 MHz, 5 ppm recommended)

- Power Supply – IOVDD: 3.3 V

- Package – 32-pin QFN-HR (5.0 x 4.5 mm)

- Temperature Range – -40 to 125°C

The ULC1001 ultrasonic lens cleaning chip is used in combination with the DRV2901 “Single-Channel PWM-input Piezo Transducer Driver” with the following key features:

- Wide 12V to 48V supply voltage operation

- Supports up to 50 W peak power

- High-Efficiency power stage with 90-mΩ output MOSFETs

- Power-On Reset for protection on power up without any power-supply sequencing

- Integrated self-protection circuits:

- Undervoltage protection

- Over temperature protection

- Overload protection

- Short Circuit protection

- Package – 44-pin HTSSOP

It’s hard to believe it will be able to properly clean lenses, but Texas Instruments further explains the technology in a separate blog post:

ULC leverages the concept of constructive interference through resonance, amplifying energy from microscopic vibrations into energy strong enough to move or atomize water. Hydrophobic and oleophobic coatings are an effective way to reduce lens polarity, optimizing the performance of ULC systems.

The resonance frequency varies depending on the nature of the contaminants, and that’s partially why there are different cleaning modes.

You can evaluate the solution yourself with the ULC1001-DRV290XEVM evaluation module based on ULC1001 and DRV290x evaluation module with features like temperature detection, lens fault detection, and contaminant detection for automatic cleaning. The kit does not come with a lens, so you’d have to install it yourself. I could not find photos of the EVM, but the video below showcases the solution with deicing, water expulsion, dirt expulsion, and give us a glimpse at the module and GUI to control cleaning modes.

The ULC1001 ultrasonic lens cleaning DSP and the DVR2901 piezo transducer driver are in mass production and can be purchased for $6.43 and $5.35 respectively in 1,000-unit quantities. The ULC1001-DRV290XEVM evaluation module sells for $249.

Thanks to TLS for the tip.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress