One method to install threaded brass inserts into a 3D printed part is to use a soldering iron. But you need to make sure to keep it vertically aligned and slowly press the insert into the plastic. A more reliable and safer method is to use a professional heat staking machine, aka thermal press machine, that typically costs over $2,000 according to the speaker in the aforelinked video.

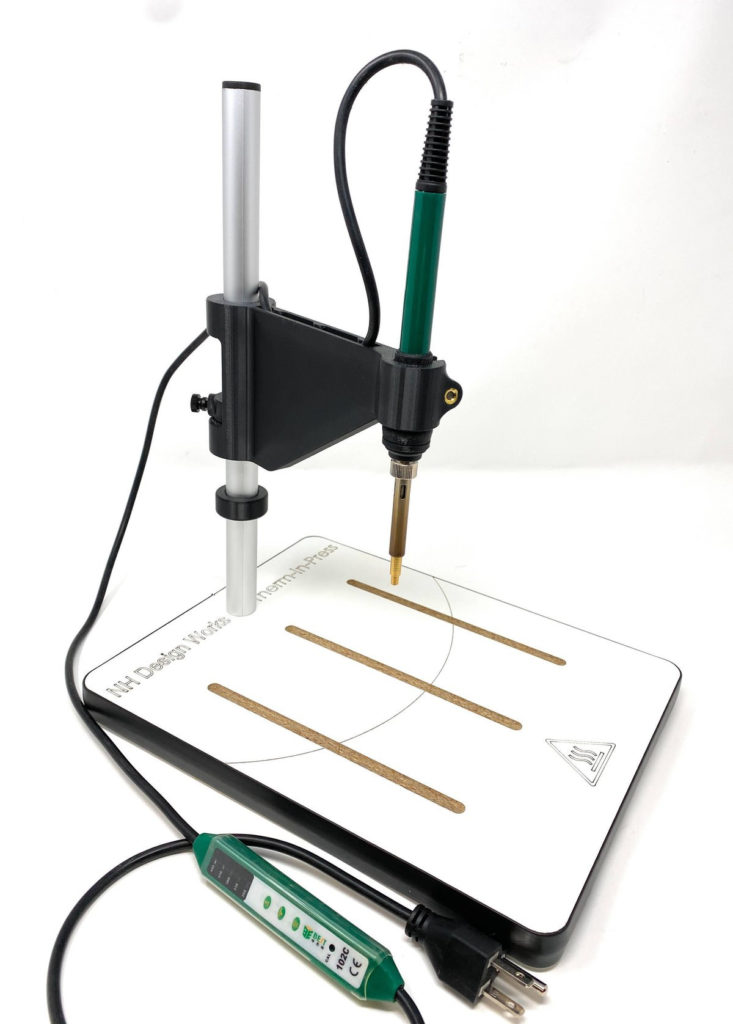

So people have come up with DIY solutions based on an off-the-shelf soldering iron and costing less than $50. Another way if you’d rather not built your own is to get NH Design Works’ thermal insert heat press sold for $99.99 on Tindie.

NH Design Works explains the heat press has some advantages including adjustable temperature, a spring return insert arm that rotates for easy alignment, tee slots for mounting tooling, and tooling for #4-40 and M3 inserts.

The Thermal Insert Heat Press is currently sold on Tindie for $99.99 plus shipping.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress