Teensy 4.0 and Teensy 4.1 are some of the most powerful microcontroller-class boards you’ll find on the market thanks to NXP i.MX RT1062 Arm Cortex-M7 crossover processor clocked at up to 600 MHz, and there won’t break the bank are PJRC sells those for $20 and up on their own store or Amazon.

If you’re into 3D printers, CNC, or pick-and-place machines, you’ll be glad to learn Teensy 4.1 board is the first Arm Cortex-M7 board to support Marlin 2.0 firmware, and a person nicknamed CrazzyFrenchDud is developing PeeNaPle breakout board for Teensy 4.1 to work with OpenPnP open-source software.

The initial commit to Marlin firmware was made on September 10 for both Teensy 4.0 and 4.1 boards, but the title was changed to Teensy 4.1 only since Teensy 4.0 is not supported at this time, and may not be suitable for many 3D printers due to a lack of pins.

Teensy 4.1 is much faster than existing boards support by Marlin firmware including EZBoard Lite with NXP LPC1769 Arm Cortex-M3 running at 120MHz and BigTreeTech SKR mini E3 control board based on STM32F407 ARM Cortex M4 running at 168 MHz. It’s unclear to me how the faster board may benefit 3D printer, but the extra performance may lead to more advanced robots powered by Marlin firmware.

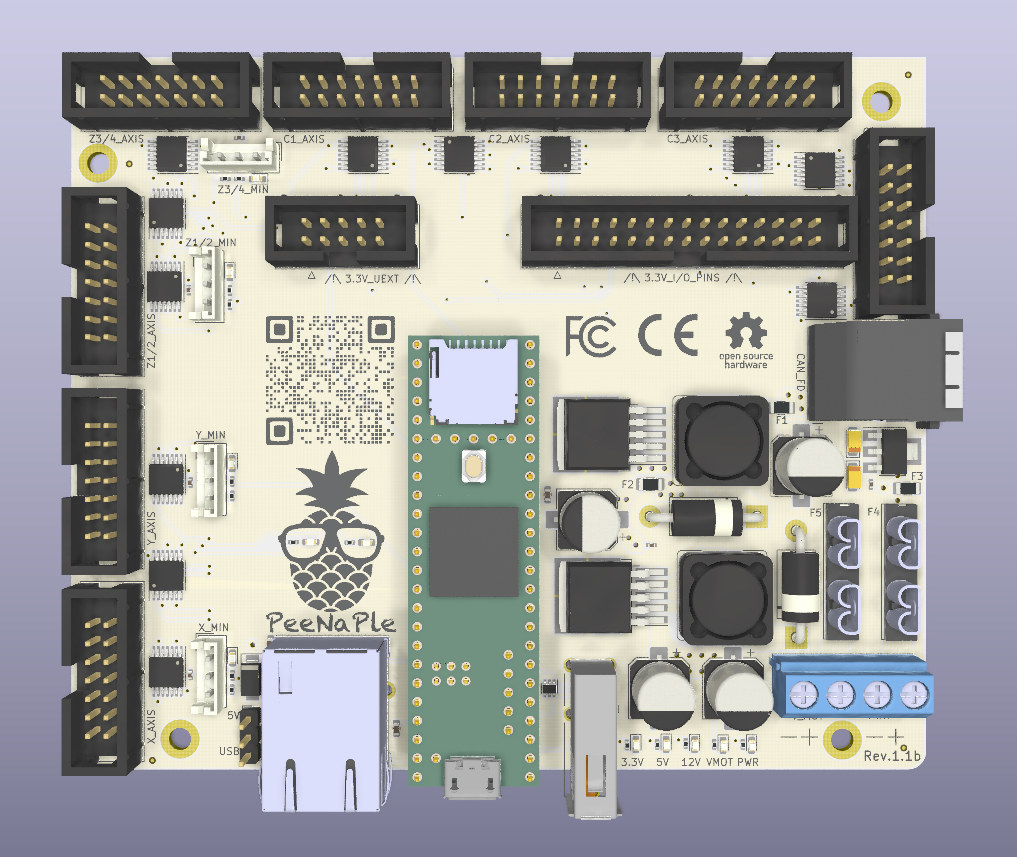

PeeNaPle board is open-source hardware with all design files released on Gitlab including KiCad schematics and GerBer files. While the board is mainly designed for pick-and-place machines using OpenPnP software, it could also be useful for 3D Printing, CNC and other Cartesian machines, and yes run Marlin firmware.

The 6-layer board includes 8x stepper outputs, 4x end_stops, an UEXT port, a USB hist port, an Ethernet port and a CAN FD bus. An adapter is being developed to let people use TMC2208/09 motor drivers, as well as a driver with closed loop capable of handling 10A. The board has a tolerance of up to 35V max power in and offers 12V, 5V/3A DCDC and 3.3V/1A.

The PeeNaPle breakout board will be available at the end of the year as a customisable kit with regular stepper motor driver adapters, high current stepper motor drivers with loop control, expansion boards etc… Crazzyfrenchdude also plans to organize a 10 boards giveaway on his Instagram account.

Thanks to Andreas for the tip.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress